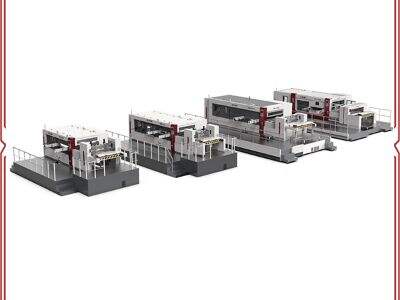

Companies producing things have to make decisions regarding the operation of thing in such a way so that the outcome of cost-efficiency can be ensured. Several companies opt for the fully automatic die cutter machine CENTURY is one of the intelligent choices, as it helps in making better and faster cuts. Here are five great reasons why this machine is such an idea.

Being More Efficient and Productive

This is because companies might get more efficiency and productiveness through fully pneumatic die-cut machines. In short, they can make products in simple ways and much quicker. All alone, without the need to have someone present to operate all the time, the CENTURY machine can cut many materials. This is extremely helpful because it saves much time in the production process. The reason for them being in one die cutting machine is that it can process different types of materials and different shapes in one run, so you do not need multiple machines. Hence, the workflow becomes way smoother. The CENTURY machine is capable of increasing the speed of the manufacturing process: it has features such as an automatic feeding system, cutting and stacking. It will enable companies to meet their targets during production.

Increased Cutting Precision and Accuracy

One other common benefit of a hand-operated die reducing machine can be that they cuts elements with plenty of precision and care. The patented CENTURY machine technology guarantees a perfect cut every time! Which means, work will take place at a higher level with no errors in the final products. The machine is very useful in delivering precise materials, and since some industries, like pharmacology, are very strict about the quality of the product, the accuracy of the pvc die cutting machine plays a very important role. Since the machine works automatically, there is reduction in human errors as well." It makes cutting process more predictable and reproducible which is important for quality level in production.

Able to work with various materials

The CENTURY machine is very versatile, as it can support all kinds of materials and designs. The operator just tells the machine what design they want and the machine cuts the material into the required design. They can be made of paper, cardboard and plastic. This can be a boon to industries such as packaging, printing, and automotive. This kind of machine enables the production of all sorts of goods depending on the needs of business. Also, the CENTURY machine is customizable according to the need of different business operations so that different business organizations are in a position to design those imaginative products to distinguish themselves from other organizations.

Save time and Labour Expense

Today, let us consider the question-of the day-how a fully automatic die-cutting machine like CENTURY can save time and money in an enterprise. As mentioned earlier, the machine is all capable of high throughput of materials without being operated continuously by manpower. That means that the companies do not necessarily need all those extra hands on deck to work the machine. This reduces labour costs substantially. It is made from extreme accurateness whereby ensures the machine creates fewer numbers of wasted products, or less inaccuracies; the costs kept on being relatively even lower this enables companies save money on operations while on full production volumes.

Better return on investment

Investing money for a complete auto-manual die cutting will make you feel less comfortable now due to how expensive these will be now; however the best return investment shall be felt by you more strongly in terms of periods. With this machine increasing efficiency and productivity, more businesses can scale their production efficiently. This is because it produces excellent quality products that satisfy customer requirements, hence making them satisfied and loyal. Corporate profitability is enhanced further through the versatility of the machine since companies can target different industries and invest in opportunities for growth in different markets. Though the cost is high at first, the savings and benefits it provides over the years make it worthwhile.

However, there can be no minor benefits of using a fully automatic die-cutting machine that urges companies to spend on it to improve efficiency, productivity, and the quality of work. It is also important in the manufacturing world, as it reduces labor time. The CENTURY machine is the choice to strive for due to advanced technology and a customizable configuration for many needs, which can be applied across most industries. The CENTURY series is the best investment, guaranteeing your success in the fastest manufacturing world.