KDYŽ jste NĚKDY viděli ten stroj, který používají k řezání kartonu s precizností? Stroj na řezání kartonu dělá právě to. Karton je obecný termín pro těžké papírové produkty s větší tloušťkou a vyšší odolností nebo jinými specifickými mechanickými vlastnostmi. Je nezbytný, protože chrání položky během dopravy ke zákazníkům.

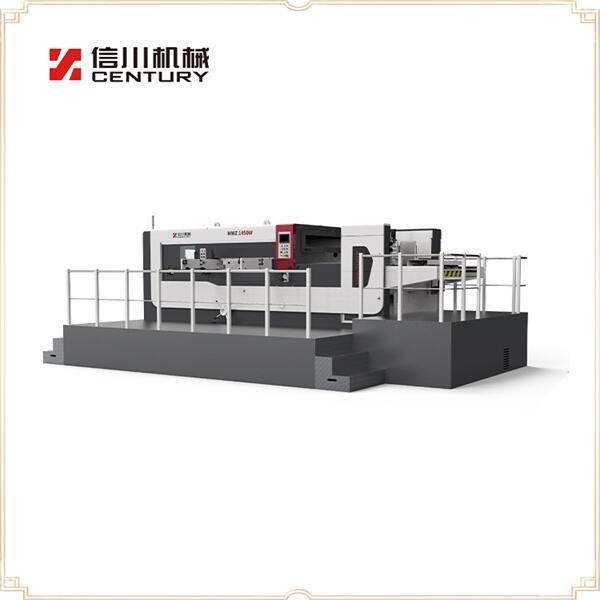

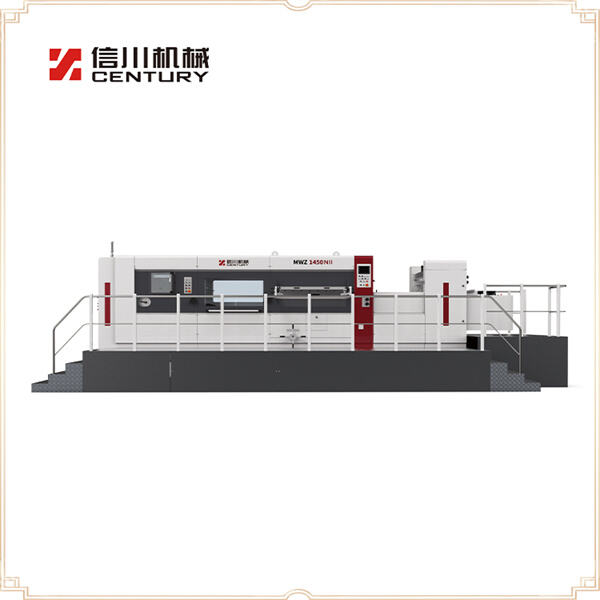

Dříve, než jste mohli ručně řezat své vlastní kartonové krabice. To vůbec nebylo snadné, stejně jako u CENTURYPoloautomatický vyřezávací stroj. Byla to spousta práce a času najít krabice, které byly přesně ve správné velikosti. S strojem na řezání kartonu je proces řezání kartonu na štěrbiny nyní mnohem rychlejší a snadnější než kdy dříve.

Takto můžeme nabídnout stroj na řezání kartonu spolu s CENTURYAutomatický vyřezávací strojje taková vynález, který umožňuje továrnám a skladům pracovat rychleji a současně. Jenom rozkáže stroji, aby vyřízl krabici ve specifikované velikosti, a všechno je hotovo. Tímto způsobem se dělníci mohou starat o jinou práci, pokud stroj zvládne všechny řezy.

Podniky, které odesílají zboží zákazníkům, musí mít dobré balení. Když podnik dopravuje produkty, je nezbytné, aby se zboží nedostalo pouze do destinace, ale bylo také bezpečné a zabezpečené během přepravy. Papírové krabice jsou slušnou formou ochrany, ale budou potřebovat být před použitím zmenšeny. Pro tohoto účelu slouží stroj na řezání papírových krabic.

V minulosti musely firmy najímat kvalifikované dělníky, kteří dokázali ručně rychle a přesně řezat krabice, než byl vynalezen stroj na řezání papírových krabic, takéInteligentní balicí linka CPU. To byl velký výzva a naučit se to trvá docela dlouho. Stroj čas a peníze vyžadované továrnami pro automatické provedení je mnohem menší, takže Aufheben Gmbhis poslední dobou.

Poté vložte kartonážní řezací stroj, je to tak rychlé, přesně jako CENTURIAVyřezávací stroj použitý. Vyrobí stovky krabic za hodinu (podle velikosti a složitosti). Tímto způsobem mohou podniky splnit objednávky mnohem rychleji a tedy přijmout více práce. Nakonec — kdo by nechtěl dostat své produkty v minimálním čase?

Vzhledem k tomu, že je materiál s vlastními velikostmi krabic využíván efektivněji, méně krabic skončí na skládkách. To je skvělé pro naši planetu. Podobně, protože je řezací proces prováděn téměř okamžitě, minimalizuje spotřebu energie. To účinně snižuje náklady na energii pro podniky, které tento stroj používají.

Shandong Century Machinery Co., Ltd. byla založena v roce 2008. Podnik je certifikován CE a ISO9001. Je to moderní regionální podnik a specializovaná národní "malá obří" společnost. Užívá si vysokého uznání a dobré reputace v obchodním prostředí. Společnost má více než 50 vysoce kvalifikovaných vědeckých pracovníků a silný technický tým pro vývoj a výrobu, který zajišťuje kvalitu a efektivnost jejích produktů. Produkty společnosti se prodávají v 29 provinciích, městských oblastech a samosprávných územích Číny a jsou exportovány do více než 60 zemí, jako jsou Spojené království, Turecko, Japonsko a další. Společnost má rozsáhlou zákaznickou a tržní základnu a její produkty jsou přijímány jak domácím, tak i zahraničním trhem. Korobková stříhací stroj.

Neustále rozvíjíme a vylepšujeme naše produkty a vyvinuli jsme širokou paletu různorodých produktů. Například kasetový papírový krmení stroj používá vektorové "stroje na řezání vlnitého papíru" bodové pohyby pro krmení papíru, bez tření a posuvu, což řeší problém škrábanců na tiskové ploše; metoda posouvání mostku vlevo a vpravo splňuje požadavky různých tiskových registrací a zajišťuje přesné pozice kartonu. Nabízíme širokou škálu modelů, jako jsou 930, 1050, 1160, 1300, 1450, 1620 atd. pro poloautomatické produkty a 1050, 1080, 1450, 1650 atd. pro fully automatické produkty, které mohou být přizpůsobeny produkční kapacitě a procesním potřebám různých zákazníků. Ve srovnání s dovozeným zařízením má stroj na plošné formování CENTURY Machinery jasnou výhodu v ceně. Výkon a kvalita produktu dokážou splnit požadavky zákazníka a navíc je ekonomická.

Plošný stroj na řezání vlnitého papíru značky CENTURY dokáže řezat vlnité papíry, ale také jiné materiály. Může být použit pro široké spektrum účelů a splnit požadavky různých klientů. Je vybaven pokročilou technologií a kvalitními materiály, jako jsou vysokopevnostní zuby a přesné mechanismy na chycení papíru, aby zajistil přesnost formovacího řezu papíru. Tlak při formovacím řezu je konzistentní a přesný, což snižuje potřebu opětovného tisku plateb. Některé modely mohou dosáhnout maximální rychlosti 7 500 listů za hodinu s vynikající efektivitou. Lze jej kombinovat s předtiskovým zařízením pro zvýšení celkové produkční efektivity. Nejnovější automatizovaný inteligentní stroj na formovací řez s úplně automatickým podáváním papíru představuje technologický rozvoj, který byl úplně vyvinut pro inteligentní automatizaci a zlepšení produkční efektivity v oblasti kvality, výroby kartonu a bezpečnosti.

Společnost se zavázala k vynikajícímu servisu pro stroje na řezání vlnitého papíru. Má komplexní systém, který může poskytovat profesionální technickou pomoc, údržbu a zákaznickou podporu a vyřešit jakékoliv problémy. Společnost je jediným "Výzkumným a vývojovým centrem plochého tlačení" v Číně uznávaným Čínskou federací balení a "Výzkumným a vývojovým centrem ploché technologie v provincii Šan-tung" oceněným Asociací balení a tisku provincie Šan-tung, a má silné výzkumné a vývojové schopnosti. Díky průběžnému investování do výzkumu a vývoje, provádění technologické inovace a zlepšování kvality našich produktů můžeme nabízet našim klientům pokročilé produkty a řešení.