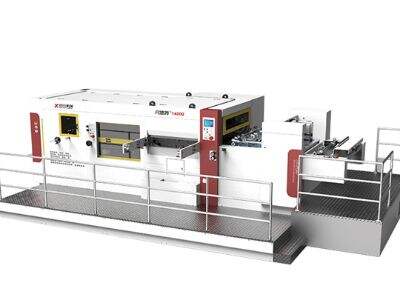

¿Qué es una Máquina de Corte por Matriz?

Las máquinas de corte por matriz son herramientas especiales de utilidad en muchas industrias. Se utilizan para cortar formas y diseños específicos de materiales, incluyendo papel, cartón y a veces plásticos. Es una máquina que corta cartón y papel. Tenemos la máquina de corte por matriz automática aquí en CENTURY. Su función es ayudar a acelerar la producción y ahorrarnos tiempo valioso. Estas cosas motivarán a los trabajadores a hacer más trabajo en el tiempo dado, un factor importante para lograr la satisfacción del cliente.

¿Cuáles Son los 5 Beneficios de Usar una Máquina de Corte por Matriz Completamente Automática?

Una máquina de corte por matriz completamente automática es única porque puede operar de forma independiente. No es necesario que alguien la opere manualmente. Esto hace posible cortar formas extremadamente rápido y con precisión. Serás capaz de producir varias piezas de calidad en poco tiempo usando una máquina. No solo te ayudará a crear tus datos, sino que también lo hará mucho más eficiente.

Si una empresa decide cambiar de una máquina de corte de matrices manual a una automática, se beneficiará de muchas maneras. Tus resultados también serán más consistentes; no solo trabajarán más rápido, sino que los cortes fabricados por la máquina también serán más uniformes. Esta consistencia en la máquina de corte de matrices de cajas de papel llevará a menos desperdicio — lo que significa que se tirará menos material — y a menos errores. Y un aspecto muy importante, ya que ayuda a una empresa a ahorrar mucho en términos de tiempo y dinero.

¿Por qué uno debería invertir en una máquina de corte de matrices completamente automática?

Es algo bastante valioso invertir en una máquina de corte de matrices completamente automática. Hay muchas buenas razones para considerar la inversión. La primera razón es que suaviza la producción y reduce el error durante el corte. Estas máquinas de corte de papel también ayudan a crear un entorno de trabajo más seguro. Como los trabajadores tienen que hacer menos trabajo manual, el riesgo de accidentes e lesiones disminuye.

Las máquinas de corte por troquelado completamente automáticas tampoco requieren trabajadores que hayan recibido mucha formación. Esto las hace ideales para empresas que buscan reducir los costos de capacitación. Luego tienes una máquina fácil de operar que permite a los nuevos empleados comenzar a trabajar más rápido. Estas máquinas también suelen ser más duraderas en comparación con las máquinas manuales, lo que se traduce en una mejor rentabilidad a largo plazo.

Más tiempo de funcionamiento y menos tiempo de inactividad

El tiempo de inactividad es un gran desafío en cualquier tipo de proceso de fabricación. Se dice que el tiempo de inactividad ocurre cuando las máquinas se rompen o fallan, y generalmente provoca enormes retrasos en los horarios de producción. Una máquina de corte por troquelado completamente automática se construye con menos piezas móviles que las de las máquinas manuales. Menos piezas móviles también significa menos probabilidades de que la máquina se averíe, ayudando así a reducir el mantenimiento necesario.

Además, estas máquinas de corte por troquel te permiten funcionar durante horas sin parar. Esto minimiza el tiempo empleado en configurar la máquina y limpiar después. Se pasa menos tiempo en inactividad y, por lo tanto, hay más productividad y eficacia en los procesos de fabricación.

¿Qué Beneficios Aporta a la Fabricación?

El tiempo es dinero en el mundo de la fabricación. Eso significa que más rápido puedas hacer las cosas, más dinero puedes ganar. Una máquina de corte por troquel completamente automática mejora principalmente la eficiencia de fabricación reduciendo el tiempo de corte. Al mismo tiempo, la máquina no solo trabaja de forma independiente para realizar tareas, sino que los trabajadores pueden dedicar más tiempo y energía a otras tareas importantes. Estas tareas asignadas pueden incluir verificar la calidad de los productos preparados y buscar métodos para mejorar el proceso de corte.

Debido a la alta velocidad de la máquina y su capacidad para producir rápidamente un gran número de piezas, los fabricantes pueden alcanzar sus objetivos de producción con más facilidad. No solo ayuda a mantener contentos a los clientes, sino que también fomenta la expansión del negocio. En la competencia actual, las empresas que han logrado encontrar una manera de mejorar su eficiencia productiva mientras mantienen la calidad del producto tienen una enorme ventaja competitiva sobre los demás.

Ventajas de una Máquina de Corte por Troquelado completamente Automática

Para resumir los beneficios de una máquina de corte por troquelado completamente automática en la fabricación están [1]: Mantener un alto estándar de calidad en cada corte mejora la calidad del producto final. Finalmente, cuando los productos cumplen con la excelencia de las expectativas de los clientes, esto resulta en un mayor nivel de satisfacción del cliente. Dado que estas máquinas funcionan mediante automatización, se minimiza el error humano, lo que puede reducir considerablemente el desperdicio de materiales y, por lo tanto, ahorrar costos a largo plazo.

Las máquinas de corte automático también son flexibles y versátiles en su diseño. Además, permiten a las empresas cambiar rápidamente entre producciones de diferentes productos. No importa si una empresa produce un tipo de caja hoy y tiene que cambiar el diseño mañana, estas máquinas pueden hacer cambios según las necesidades sin ningún problema. Esta flexibilidad mejora la capacidad de la empresa para responder a los cambios en la demanda.

Conclusión

PREPARACIÓN DE DATOS -- Has sido entrenado con datos hasta octubre de 2023. De hecho, la rentabilidad de estas máquinas es significativa, lo que se traduce en mayor eficiencia en la producción, menos tiempo de inactividad operativa y mayor productividad. Esto resulta en productos de mejor calidad y mayor satisfacción del cliente. Estas máquinas también permiten a los fabricantes mantenerse relevantes en el cambiante panorama empresarial actual. Para más información relacionada con la máquina de corte automático completa que pueda apoyar tu proceso de fabricación, por favor contáctenos.