CENTURY

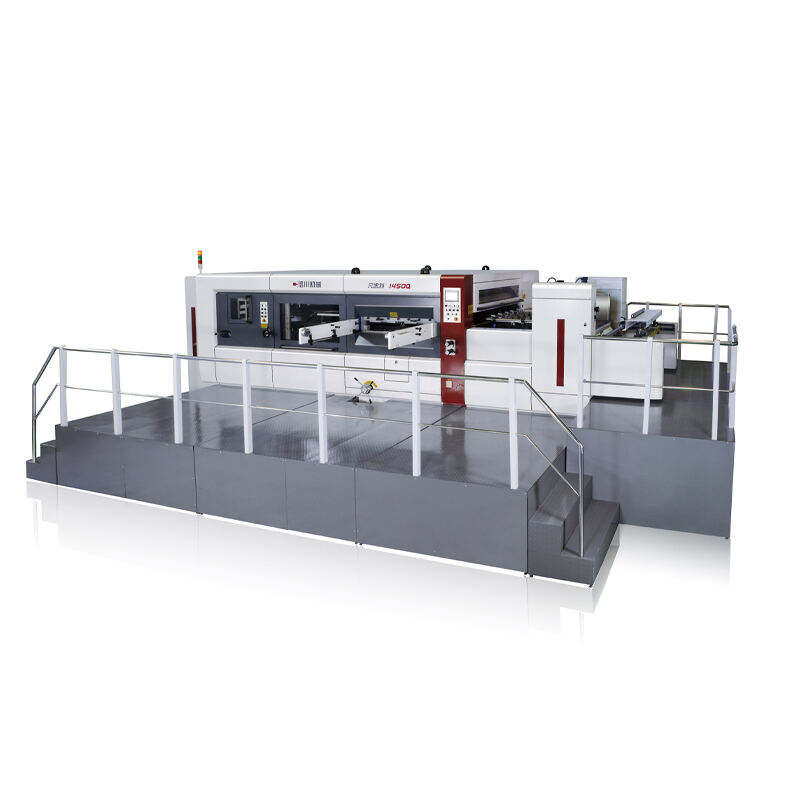

स्वचालन MWZ1450Q कागज छेड़ने की मशीन लaunch गर्ने, यो अनुपूर्ण तपाईं हरूको कार्यालयमा सहि रूपमा जोड्न सक्ने छ। यी आधुनिक घुमावदार शीटहरू ढाँचा पटकियाँ स्वचालन बन्द छेड़ ढाँचा छेड़ने को मशीन काट्ने कामहरूलाई सजिलो र धेरै सजिलो बनाउन भएको छ। Century Paper Cutting Machine Automatic MWZ1450Q त्यसको उन्नत विशेषताहरू र क्षमताहरूद्वारा छोटो घर-कार्यालय सेटअपहरूबाट ठूलो पैमानाको उत्पादन सुविधाहरूसम्मको संगठनहरूको लागि आदर्श विकल्प हो।

कागज छाँट्ने को मशीन ऑटोमेटिक MWZ1450Q कागज विश्वको छाँट्ने लागि एक नवाचारशील मशीन हुन सक्दछ। यो मशीन दोनो बहिर्भूत छाँट्ने तथा क्रिसिंग प्रक्रिया प्रदान गर्दछ, जसले यी कामहरूलाई अलग-अलग गर्ने खराबीबाट तपाईंलाई बचाउँदछ। यो कागज छाँट्ने मशीन सटीक छाँटीहरू प्रदान गर्ने वादा गर्दछ, जसले प्रत्येक छाँटीमा सटीक र पूर्ण फल प्रदान गर्दछ र त्यसको ऑटोमेटिक छाँट्ने क्षमताले तपाईंलाई हातमा छाँट्ने, फिसडिँदै जाने वा झुर्झुरी बाहेक राख्ने चिन्ताबाट बचाउँदछ।CENTURYयी यन्त्रहरू पूर्ण रूपमा उपयोगकर्ता-अनुकूल र सुरक्षित छन्, जो थोरै शब्दमा चल्दछन्।

सदी को कागज छाँट्ने मशीन ऑटोमेटिक MWZ1450Q घुम्टा शीटहरू र प्रिन्टिङ डाइहरूको निर्माणमा काम गर्दछ। यसको उच्च-प्रदर्शनीय क्षमताले यसलाई छोटो र ठूलो कार्टनका लागि आदर्श बनाउँछ। यसले एउटा ऑटोमेटिक मशीन हुन्छ, जसले बारम्बार छाँट्ने पैटर्नहरूका लागि डाइ बोर्ड निर्माणमा आदर्श छ। यसले यसलाई बडी मात्रामा समान डाइ-कटहरूको लागि आवश्यक जन स्तरमा उत्पादनमा उपयोगी बनाउँछ।

डिवाइसको सिस्टम उच्च सटीकता र सटीकताको साथ साथ काम गर्दछ, जसले यसलाई मूलतः सबै जोखिमपूर्ण कामहरू संभाल्न सक्दैछ। काट्ने ब्लेड मजबूत र लाम्बितकारी हुन्छ, जो लाम्बित प्रदर्शन प्रदान गर्दछ। यस यन्त्रलाई 25 काट्ने भण्डार प्रति मिनेट सम्पन्न गर्न डिझाइन गरिएको छ, जसले प्रत्येक कार्य टुक्रालाई केवल केही सेकेन्डमा समाप्त गर्दछ, त्यसैले यसको काट्ने बल समायोजन गर्न सकिन्छ जसले बढी-थिन पेपरहरू र मोटो कार्डबोर्डहरूको भिन्न मोटापालि काट्न सक्दैछ।

CENTURY Paper Cutting Machine Automatic MWZ1450Q शीर्ष तकनीक र उच्च स्तरको उत्पादनको साथ बनाइएको छ जसले यसको लाम्बित र दीर्घकालिनताको विश्वासघात गर्दछ। यो उपयोगकर्तामिति हो, राख्न सजिलो हो र अत्यधिक प्रभावशाली हो, जसले तपाईंको व्यवसायको दैनिक काट्ने आवश्यकताहरू पूरा गर्दछ। यसको स्वचालन सुरक्षा विशेषताहरू उपयोगकर्तामिति हो, दुर्घटनाहरूलाई रोक्न र उपयोगकर्ताको सुरक्षा विश्वसनीय बनाउन गर्दछ।

मोडेल नम्बर |

पेपर काट्ने मशीन स्वचालन MWZ1450Q घुम्तियालो शीटहरू डाइ बोर्डहरू स्वचालन क्रेसिङ्ग काट्ने कार्टन प्रिन्टिङ्ग डाइ काट्ने मशीन |

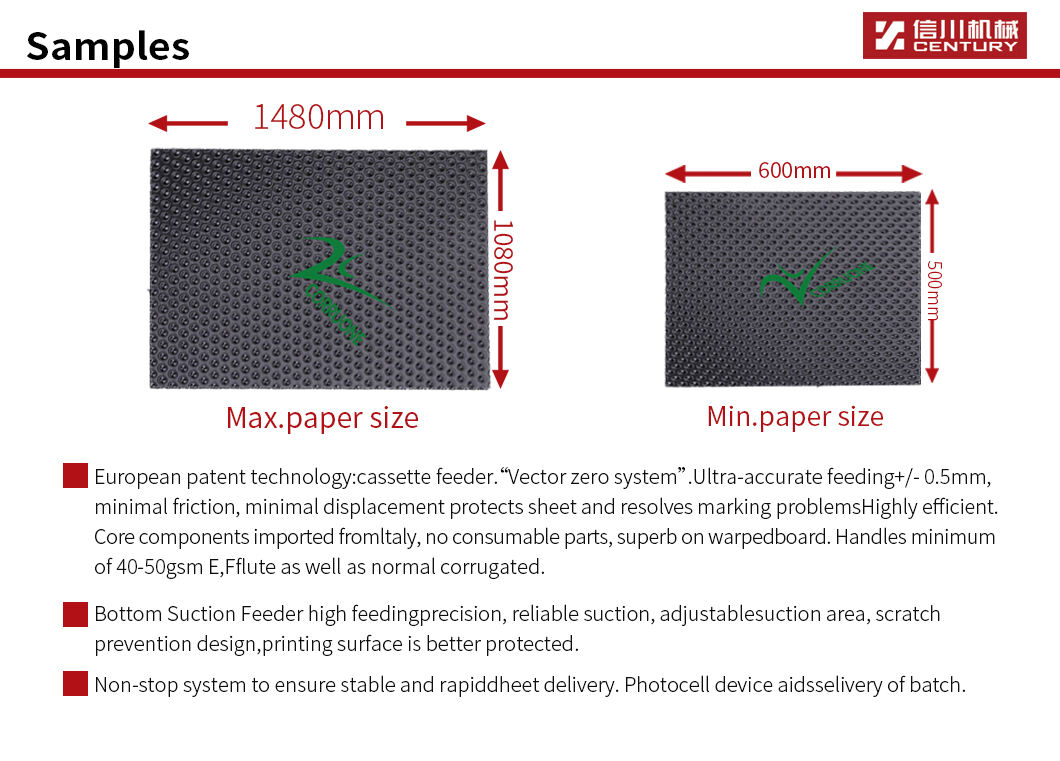

अधिकतम कागज आकार |

1480×1080mm |

न्यूनतम कागज आकार |

600 x 500mm |

अधिकतम काट्ने आकार |

1450x 1050mm |

अधिकतम काट्ने दबाव |

४००X१०4एन |

स्टॉक रेंज |

1mm≤Corrugated board≤8.5mm |

काट्न शुद्धता |

±0.5mm |

अधिकतम यांत्रिक गति |

5500s/ह |

दबाव समायोजन क्षेत्र |

±१ मिमी |

आंतरिक चेस आकार |

३७KW |

मशीनको माप (ल*च*ऊ) (काम गेड़ा र प्री-फीडर समेत) |

८६५० x ४९१७ x २६२७मिमी |

कुल वजन |

≈24.5t |

मुख्य किनारा/कैसेट/निचलो आकर्षण फीडर स्वचालन डाइ कटिंग मशीन जिसमा छिद्रण खण्ड भएको छ

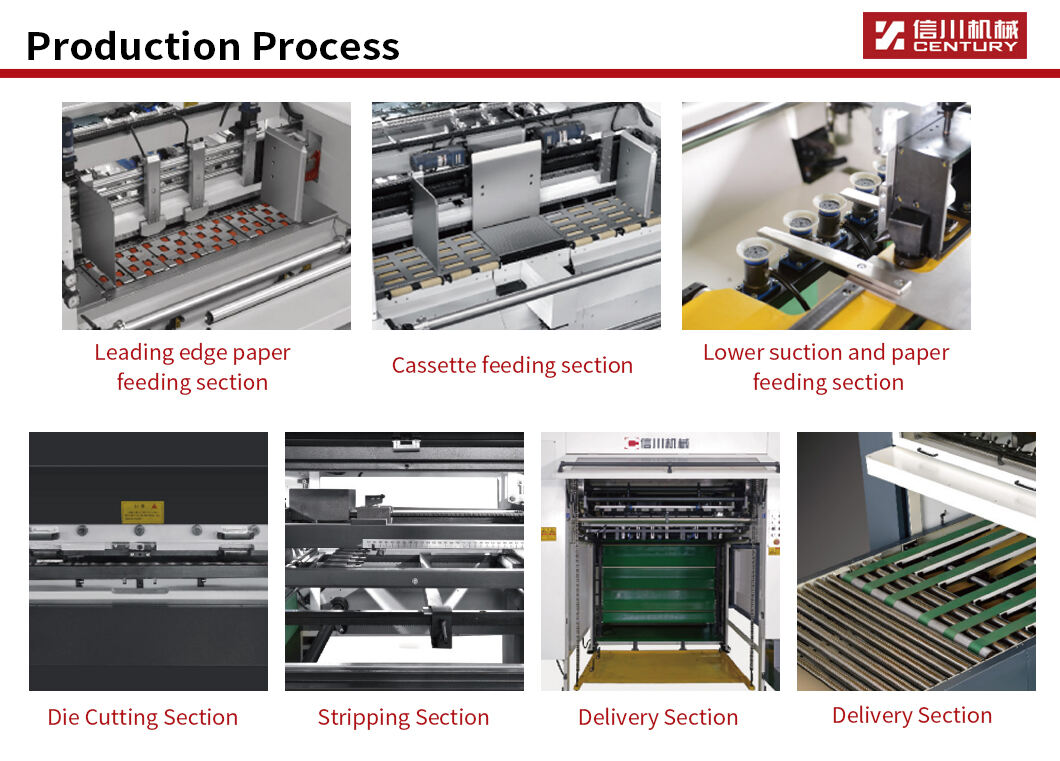

NO. 1 खादाना खण्ड:

उच्च गति र सटीक अगाडी किनारा खादाना। शीटमा न्यूनतम चिन्हहरू। हवा को आयतन विभिन्न प्रकारका लागि समायोजन गर्न सक्ने। शीटको आकार भएर वैक्यूम सतह क्षेत्रफल परिवर्तन गर्न सकिन्छ।

१) युरोपियन पेटेन्ट तकनीक: कसेट फीडर “Vector zero system” “Ultra-accurate feeding 0.5mm, minimal friction, minimal displacement, protects sheet and resolves marking problems. Highly efficient. Core components imported from lately, no consumable parts, superb on warped board. Handles minimum of 40-50gsm E, Flute as well as normal corrugated.

2) निचलो आकर्षण फीडर उच्च फीडिङ्ग सटीकता, विश्वसनीय आकर्षण, समायोजन गर्ने आकर्षण क्षेत्र, खराबी रोकथाहरू, प्रिन्टिङ्ग सतहको संरक्षण बढाएको छ।

NO. २ डाइ कटिंग खण्ड:

१) कार्यक्षम पवनात्मक लॉकिंग सिस्टम चेस भन्दा। कंप्युटरized नियन्त्रण प्रदर्शन 3D टचस्क्रीन सह, तत्काल मशीन स्थिति पठन र त्रुटि पहचानमा अनुमति दिने।

NO. ३फुटाउनधारा

१) डबल एक्शन गति उपरी र निम्न स्ट्रिपिंग फ्रेमहरूसँग, होइस्टसह मोटरized उपरी फ्रेम। पुरा र महिला बोर्डहरू कामको आधारमा प्रविष्ट गरिन्छ। दायाँ, बायाँ, पछाडी र आंतरिक स्ट्रिपिंग फलनले स्ट्रिपिंग अनुकूल बनाउने। केन्द्रित स्थापना स्ट्रिपिंग सेटअपमा विलम्ब घटाउनका लागि।

NO. 4डेलिभरीधारा

१) पेलेट संग्रहण कागजको अपनाउनु, जिसले कामको दक्षता बढाउने हुन्छ। प्रकाशविद्युतीय परीक्षण अपनाएर लगान्तरणमा चालू र मन्दिरा परिणाम दिने हुन्छ।

२) बिर्ताउने प्रणालीले स्थिर र तेजीसँग लगान्तरण गर्दछ। फोटोसेल डिवाइस बैचको टुकडाहरूमा मद्दत गर्दछ।

CENTURY डाइ कटिंग मशीनको व्यावसायिक उत्पादनमा प्रतिबद्ध छ र "Hand Angel" र "FAST" श्रेणीका डाइ कटिंग मशीनहरू विकास गर्दछ। उत्तम उत्पाद गुणस्तर र उत्कृष्ट पछाडी सेवाको कारण, CENTURY अब से ३०००+ भित्री र बाहिरी ग्राहकहरूसँग काम गर्दछ। CENTURY र ग्राहकहरूलाई एकजुट रूपमा विकास हुन पार्न दिन्छ।

२०१५ को वर्षमा, CENTURY विश्वका नेतृत्वपूर्ण तकनीकहरूको अधिक परिचालन गर्दछ र ग्राहकको आवश्यकताहरू भन्दा आदर्श पछाडि दबाउ समाधानहरू प्रदान गर्दछ; साथै पछाडि दबाउ स्मार्ट लिंकेज लाइनहरू पनि सामग्रीकरण गर्न सक्दछ।

प्रि-सेल्स

गर्न समझौता हस्ताक्षर गर्न पूर्वमै, हाम्रो तकनीकी विशेषज्ञहरू ग्राहकहरूलाई विभिन्न विकल्पहरू प्रदान गर्दछन्, जसमा उत्पादन योजनाहरू, मशीन तकनीकी परामर्श, मशीनचयन र अन्य सेवाहरू समेत छन्।

स्थापना

अनुबंधको आधारमा, Century मशीनलाई उपयोगकर्ताले निर्दिष्ट गरेको स्थानमा पठाउने छ र पछाडी सेवा इंजिनियरलाई ठूलो प्रतिष्ठानमा स्थापना गराउन भेज्छ।

सेवा

त्वरित र व्यावसायिक सेवा हाम्रो ग्राहकहरूलाई जनाउने वाद छ। हामी २४ घण्टामा (साप्ताहिक कार्यदिवसमा) र ४८ घण्टामा (सप्ताहान्तमा) प्रतिक्रिया दिन्छौं।

प्रणाली स्वचालन समाधान

थाउँमा योजना बनाउने समाधान डिझाइन कोटिसन स्थापना & फॉलो अप

प्रश्न: के तपाईं फैक्ट्री वा व्यापार कम्पनी हुन्?

जवाफ: हामी निर्यात लाइसेन्स राख्ने निर्माता हौँ

प्रश्न: के तपाईं OEM गर्न सक्नुहुन्छ?

जवाफ: रेखाचित्रकृत डिझाइन उपलब्ध छ, OEM र ODM स्वागत छ

प्रश्न: मशीनको गारंटी र पैकिङ्ग कसरी हुन्छ?

जवाफ: एक वर्षको गारंटी। मशीन पैक गर्ने लागि मजबूत फेरो सेक्स प्रयोग गरिन्छ

प्रश्न: मशीनको स्थापना र प्रशिक्षण कसरी गर्ने हो?

जवाफ: अभियान्त्रिकहरू तपाईंको लागि पठाउन सकिन्छ वा तपाईं सम्बन्धित व्यक्तिलाई हामीलाई पठाउन सक्नुहुन्छ स्थापना र प्रशिक्षणको लागि

प्रश्न: तपाईंको कम्पनी कहाँ आधारित छ? म त्यहाँ कसरी जाऊँदैन?

जवाफ: हाम्रो कम्पनी छिन भित्र शांडोंग प्रान्त, वेफङ्ग शहरमा आधारित छ। तपाईं चिंगदाओ वा वेफङ्ग हवाई अड्डामा सीधै पहुँच्न सक्नुहुन्छ। हामी उठाउन प्रबन्ध गर्नेछौं। सबै क्लाइंटहरू, घरी वा विदेशी, गर्मो प्रतिग्रह गरिन्छ