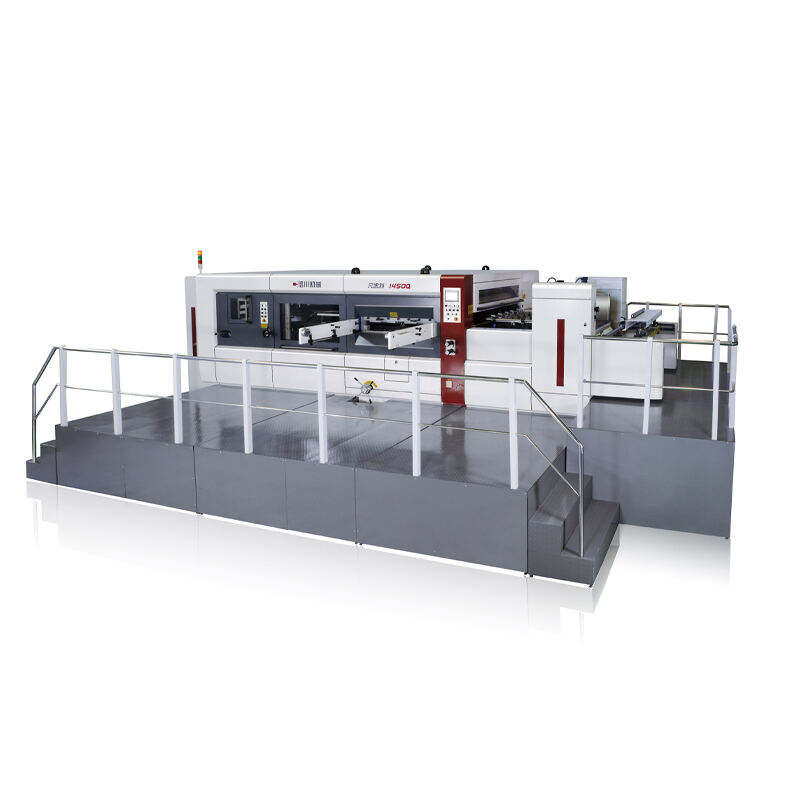

Have you ever wondered just how a large number of shaped cardboard boxes are created? Meet the corrugated box die cut machine MWZ1450Q flat bed die cutting machine and die cutting machine automatic. This machine was built with innovative machine that can cut paper, cardboard, and also other materials into different sizes and shapes for packaging and paper-related services and products.

It is a vital device to any production and packaging business. This flat bed cutting machine can take on bins up to 1450mm x 1100mm. The machine provides an extraordinary production by having an optimum cutting speed of 28 times for each minute.

The MWZ1450Q flat bed cutting machine is sold with the latest technology, which makes it extremely user friendly. The machine includes a die hoist, photo detection, and a waste elimination system. Furthermore, the die cutting machine also has automated lubrication that offers the benefit of increased durability and dependability.

One of the most striking options that come with this is its effectiveness. The die automated machine can cut dissimilar forms, right cut, and perforate cardboard with unparalleled precision. The machine comes with a solid competitor on the market with error-free cutting and freedom.

The CENTURY brand prides itself on delivering products which place client satisfaction first. The Corrugated Box Die Cut Machine isn't any exclusion, plus it saves on manufacturing time, hence increasing efficiency. The machine can be personalized to complement the options of clients featuring its smart design.

The corrugated box die cut machine MWZ1450Q flat bed die cutting machine and die cutting machine automatic is fantastic for an array of organizations, including packaging, publishing, marketing, and a lot more. The machine is incredibly versatile and can cut almost every number of product, including corrugated paper, cardboard, synthetic, plastic, and foam

corrugated box die cut machine MWZ1450Q flat bed die cutting machine and die cutting machine automatic

Model Number |

Automatic Die Cutting Machine |

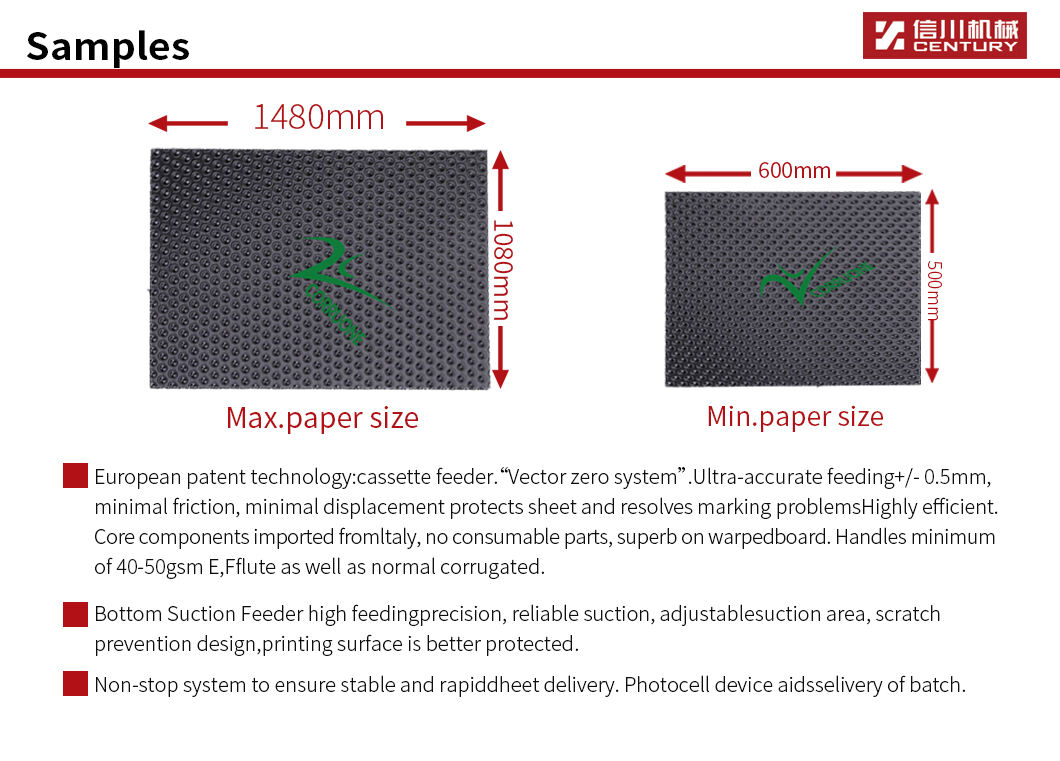

Max. Paper Size |

1480×1080mm |

Min. Paper Size |

600 x 500mm |

Max. Cutting Size |

1450x 1050mm |

Max. Cutting Pressure |

400x104N |

Stock Range |

1mm≤Corrugated board≤8.5mm |

Cutting Precision |

±0.5mm |

Max. Mechanical Speed |

5500s/h |

Pressure Adjusting Range |

±1mm |

Inner Chase Size |

37kw |

Machine Dimension L*W*H Include the work platform, pre feeder |

8650 x 4917 x 2627mm |

Total Weight |

≈24.5t |

Lead edge/Cassette/Bottom Suction feeder automatic die cutting machine with stripping section

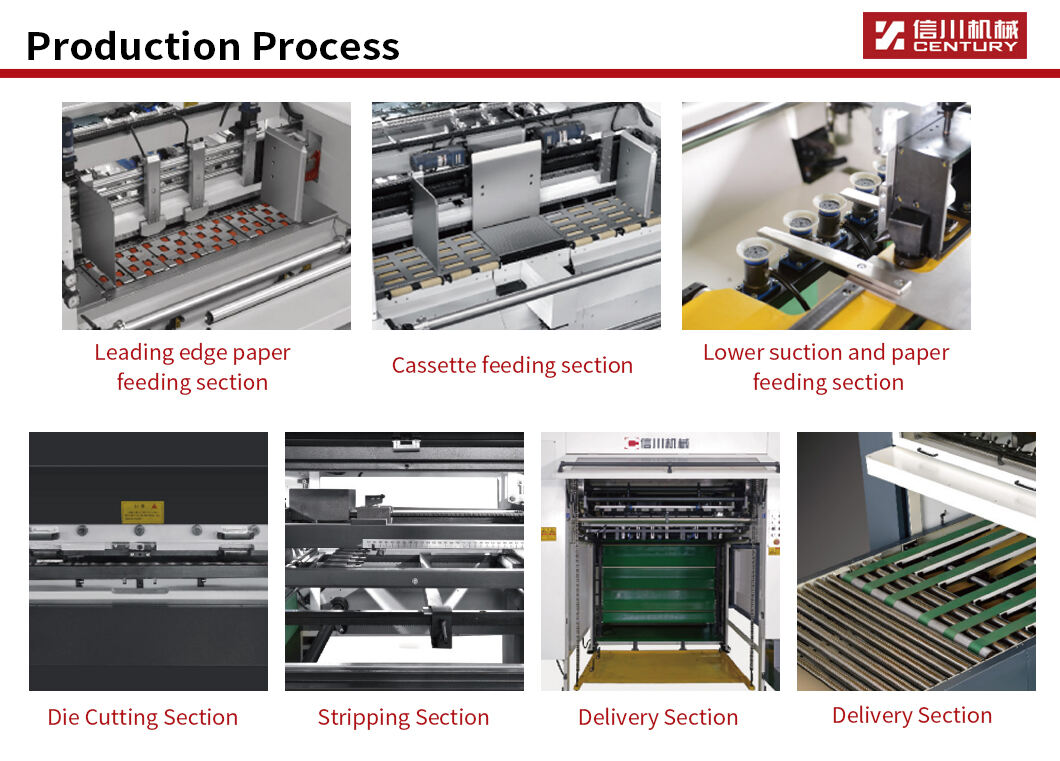

NO.1 Feeding Section:

High speed and precise lead edge feeder. Absolute minimal marking to sheet. Air volume control adjustable to different grades handled. Vacuum surface area variable subject to sheet size

1) European patent technology:cassette feeder “Vector zero system" Ultra-accurate feeding+/- 0.5mm, minimal friction, minimal displacement, protects sheet and resolves marking problems. Highly efficient. Core components imported from ltaly, no consumable parts, superb on warped board. Handles minimum of 40-50gsm E, Fflute as well as normal corrugated

2) Bottom Suction Feeder high feeding precision, reliable suction, adjustable suction area, scratch prevention design, printing surface is better protected

NO.2 Die Cutting Section:

1) Efficient pneumatic locking system for chase. Computerised control display with 3D touchscreen, allowing instant machine status reading and error indentification

NO.3 Stripping Section

1) Double action movement with upper and lower stripping frames, motorised upper frame with hoist. Male and female boards inserted subiect to desired job. Right, left, rear and internal stripping function to optimise stripping. Centralised positioning to reduce downtime on stripping set-up

NO.4 Delivery Section

1) Adopt the pallet collection paper, flexible and comfortable, to increase the work efficiency. Adopt photoelectric detection to insure smooth and steady delivery

2) Non-stop system to ensure stable and rapid sheet delivery Photocell device aids delivery of batch

Before signing the contract, our technician provides customers with various options, including production plans, machine technical consulting, machine selection and other services

Installation

According to the contract, Century will transport the equipment to the installation site designated by the user, and send the after-sales service engineer to install on site