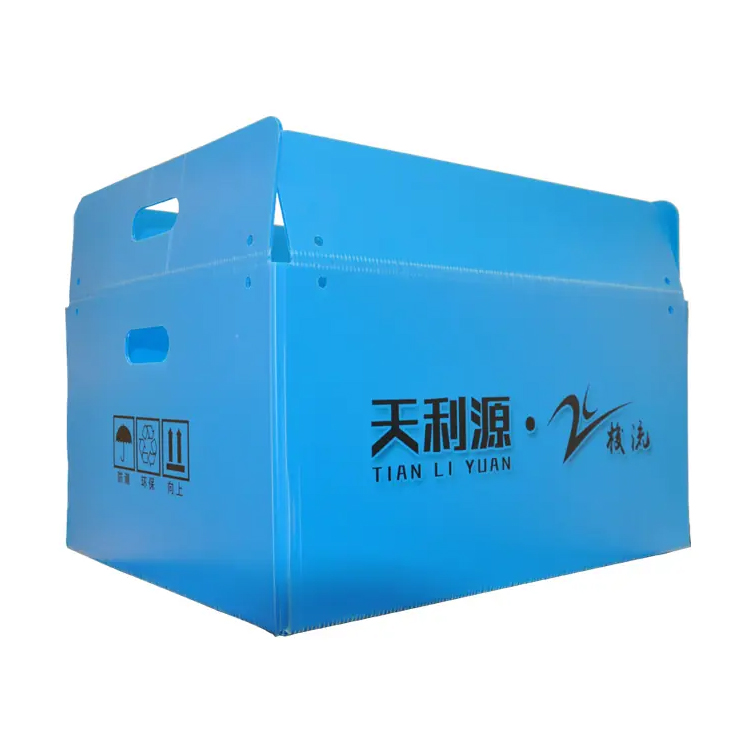

The CENTURY’s corrugated box die cut machine is a vital device to any company that needs top-notch die-cutting abilities. This effective and dependable device was created to manage many materials, including paper, cardboard, and synthetic, which makes it the best solution for packaging and publishing businesses.

Featuring advanced level technology, the MWZ1450QZ die cutting device has an effective engine that provides fast and efficient cutting abilities. This accurate and machine was built to deliver constant cuts each and every time, rendering it a great option for companies that need high quantities of accuracy and precision of their manufacturing procedures.

The automated flat bed cutting device is another excellent item from CENTURY. This revolutionary product was made to offer effectiveness and maximum precision, all while reducing manufacturing times and expenses. Its advanced feature levels make it perfect for large-scale productions, where time-bound deliveries are crucial.

The automated system linked to the CENTURY corrugated box die cut machine is equipped to address big volumes of materials with just minimal human intervention. This high-speed device makes it feasible to cut and crease cardboard, plastic materials, along with other materials with accuracy at even more quick rate than handbook techniques. And thus of the automatic system, it offers a far more efficient and structured production process.

The CENTURY’s automated flat bed cutting machine features state-of-the-art technology that delivers accurate and constant performance each and every time. Its automatic system ensures that materials are regularly and accurately placed, while its high-speed cutting and creasing abilities guarantee fast and efficient production.

Both the MWZ1450QZ die cutting device and the automated flat bed cutting device are made with individual convenience in mind. They function with intuitive settings and interfaces to make sure they are user-friendly are simple to run. In addition, they include step-by-step manuals and support, making sure every individual could get the most from their investment

Model Number |

Automatic Die Cutting Machine |

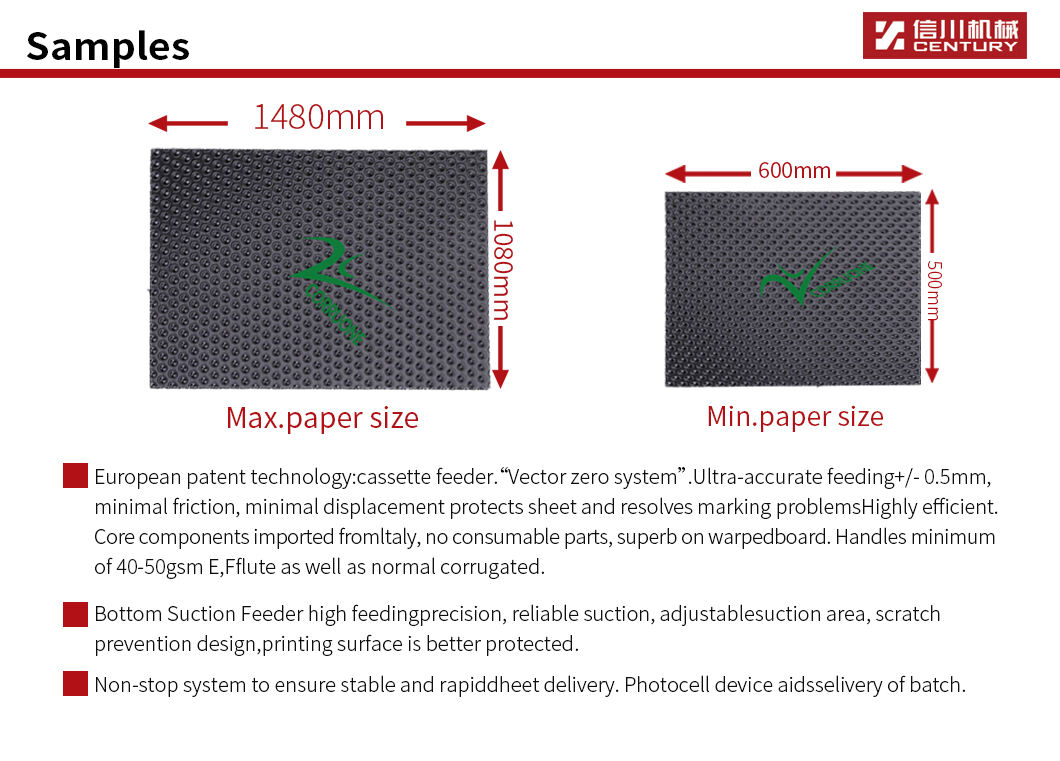

Max. Paper Size |

1480×1080mm |

Min. Paper Size |

600 x 500mm |

Max. Cutting Size |

1450x 1050mm |

Max. Cutting Pressure |

400x104N |

Stock Range |

1mm≤Corrugated board≤8.5mm |

Cutting Precision |

±0.5mm |

Max. Mechanical Speed |

5500s/h |

Pressure Adjusting Range |

±1mm |

Inner Chase Size |

37kw |

Machine Dimension L*W*H

Include the work platform, pre feeder |

10231 x 4917 x 2327mm |

Total Weight |

≈25t |

Lead edge/Cassette/Bottom Suction feeder automatic die cutting machine with stripping section

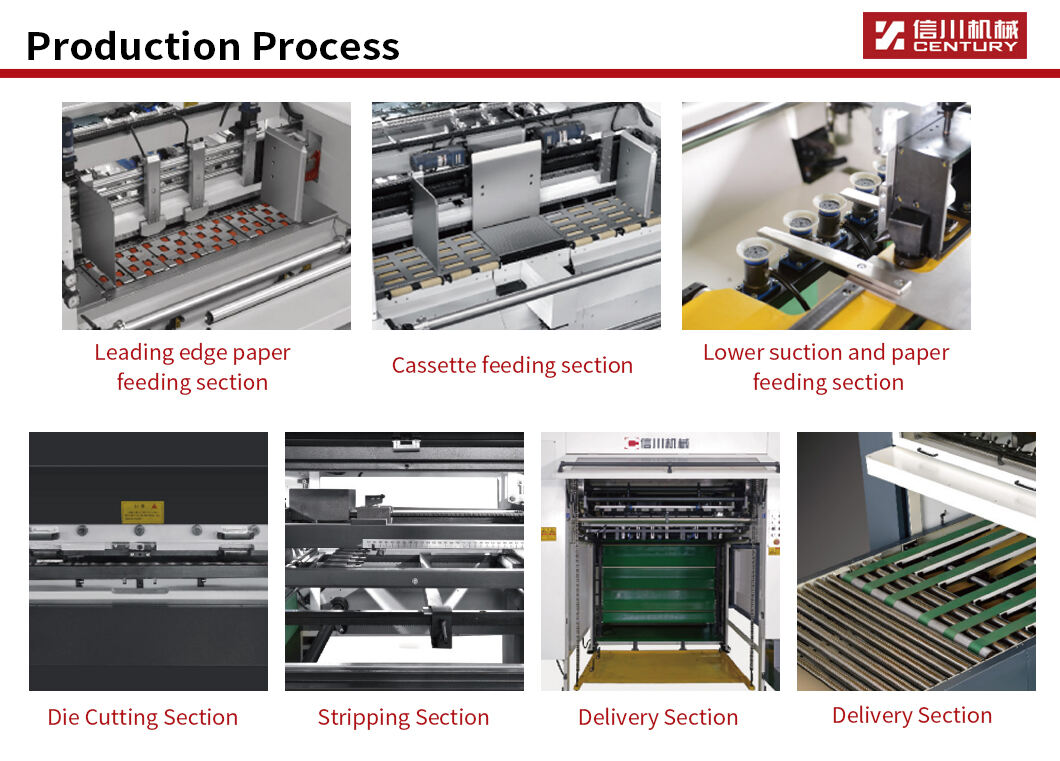

NO.1 Feeding Section:

High speed and precise lead edge feeder. Absolute minimal marking to sheet. Air volume control adjustable to different grades handled. Vacuum surface area variable subject to

sheet size

1) European patent technology:cassette feeder “Vector zero system" Ultra-accurate feeding+/- 0.5mm, minimal friction, minimal displacement, protects sheet and resolves marking problems. Highly efficient. Core components imported from ltaly, no consumable parts, superb on warped board. Handles minimum of 40-50gsm E, Fflute as well as normal corrugated

2) Bottom Suction Feeder high feeding precision, reliable suction, adjustable suction area, scratch prevention design, printing surface is better protected

NO.2 Die Cutting Section:

1) Efficient pneumatic locking system for chase. Computerised control display with 3D touchscreen, allowing instant machine status reading and error indentification

NO.3 Stripping Section

1) Double action movement with upper and lower stripping frames, motorised upper frame with hoist. Male and female boards inserted subiect to desired job. Right, left, rear and internal stripping function to optimise stripping. Centralised positioning to reduce downtime on stripping set-up

NO.4 Delivery Section

1) Adopt the pallet collection paper, flexible and comfortable, to increase the work efficiency. Adopt photoelectric detection to insure smooth and steady delivery

2) Non-stop system to ensure stable and rapid sheet delivery Photocell device aids delivery of batch

Company Profile

CENTURY is committed to the professional manufacture of die cutters under the "Hand Anger" and "FAST" brands. Over a comparatively short period

CENTURY has generated a customer base of some 5,000 domestic and overseas clients, building relationships to enable both parties to grow

CENTURY took a further technological step and introduced the CPU line, a sophisticated high volume production line designed to the specific needs of customers. The CPU is an Intelligent Line combining pre-feeder, Flexo print, die cutting, strapping, robotic handling and other selected units. During 2016 Century Machinery achieved the title "Famous Brand of Shandong" through the Shandong Industrial Design Centre and was awarded High-tech Enterprise Company status. It currently owns 9 patents, 14 utility models with 39 intellectual property rights on its inventions and products

Century is proud to be recognised as professional and innovative in turnkey solutions of post-press equipment

Currently Century is serving business 5000 partner in more than 50 cou ntries around the words

The development of technology is infinite! To drive the industry forward Century Machinery has forged part-nerships with well-respected manufacturers from the world of corrugated board. The core of our future global strategy is to be the leading force of turnkey solutions for Post-press equipment

Pre-salesBefore signing the contract, our technician provides customers with various options, including production plans, machine technical consulting, machine selection and other services

Installation

According to the contract, Century will transport the equipment to the installation site designated by the user, and send the after-sales service engineer to install on site

Service

Prompt and professional service is our promise to customers. We will react in 24 h for weekdays and in 48 h for weekends

System Automation Soulution

On site planning —— Solutions —— Designing —— Quotation —— Installation & Follow up

Q: Are you a factory or trading companyA:We are manufacturer with the export license

Q: Can you do OEM

A: Customized design is available, OEM and ODM are welcomed

Q: How is the warranty and packing of the machine

A: ONE YEAR WARRANTY. strong steel cases are used for packing the machine

Q: How to install and training of the machine

A: Engineers can be sent to you for training, or you can send related person to us for installation and training

Q: Where is your company located? How can I visit there

A: Our company is located in Weifang City, Shandong Province, China. You can fly to Qingdao or Weifang airport directly. We would arrange the pick-up. All clients, from home or abroad are warmly welcomed