CENTURY

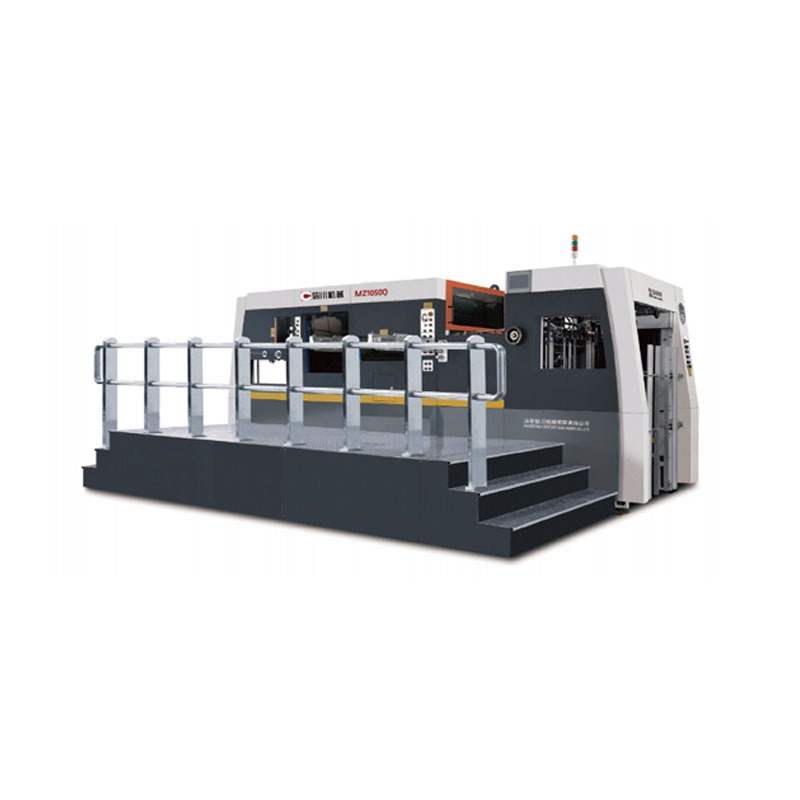

In most it is the packaging and printing industry, the Flat bed cutting machine MZ1050Q lat bed die cutting automatic corrugated rotary die cutting machine is one device that any into cannot do without. This revolutionary product gives you the effectiveness greater in cutting easy in cutting and accuracy to your material.

with this automatic corrugated rotary die cutting machine such materials will be easy to handle no matter whether it is paper, cardboard, corrugated board, foam or plastic. The CENTURY firm’s rotary blades no longer only lead as much as the cutting process faster but gives your finished product a more polished glow. This revolutionary product is designed to improve your productivity and the services that can assist you in suits your Payment dates with a maximum cutting capacity of five thousand sheets in one hour.

The CENTURY Brand Flat bed cutting machine MZ1050Q lat bed die cutting automatic corrugated rotary die cutting machine and I can tell you that you do not have a tough time operating and setting up a control in the rate and pressure and the blades section of the equipment. The designed PLC system is easy to use and greatly simple, which makes the used equipment comparatively simple in usage and operation for those who have just joined this line.

The other benefit of this flat bed die cutting machine is that it is very stable and has a strong structure that cannot be compared. The engineered design of the gear ensures that the watt hours are manufactured for heavy and continued usage making it a sound investment in the run long. It has an integrated CNC top-notch system which assists you with the precision cutting to minimize waste, therefore, saving you lots of cash on the materials.

The CENTURY bed flat machine MZ 1050Q provides safety precautions necessary for avoiding accidents with our decreased risk of accidentally harming the equipment with its anti-collision feature. and its self-flushing oil lubrication system goes a long way in ensuring that there is smooth running of the equipment thereby eliminating the time frequent calls for oil lubrication and the related expenses would be incurred

Model Number |

Automatic Die Cutting Machine |

||||||

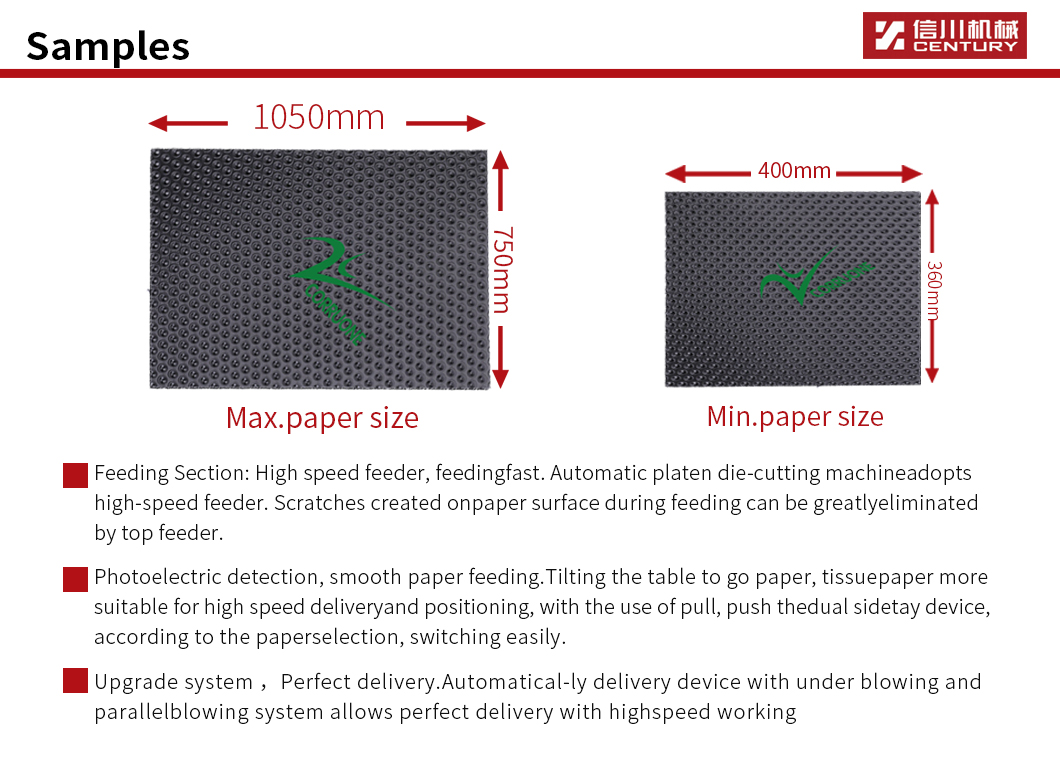

Max. Paper Size |

1050×750mm |

||||||

Min. Paper Size |

400×360mm |

||||||

Max. Cutting Size |

1040×730mm |

||||||

Max. Cutting Pressure |

300×104N |

||||||

Stock Range |

Cardboard 90-2000g corrugated cardboard ≤ 4 |

||||||

Cutting Precision |

±0.1mm |

||||||

Max. Mechanical Speed |

7500s/h |

||||||

Pressure Adjusting Range |

±1mm |

||||||

Min. front margin |

8mm |

||||||

Inner Chase Size |

1140×756mm |

||||||

Total Power |

21kw |

||||||

Machine Dimension(L*W*H) (Include the work platform, pre-feeder) |

6000×4400×2400mm |

||||||

Total Weight |

≈17t |

||||||

CENTURY is committed to the professional production of die cutting machine, and has developed "Hand Angel"and "FAST" series of die cutting machine. With good product quality and excellent after-sales service, CENTURY has developed more than 3000 domestic and overseas customers. Enable CENTURY and customers to grow together.

In the year of 2015, CENTURY made further integration of the world leading technology, and provided ideal post-press solutions according to customer's demand; and can also customize post-press intelligent linkage line

Pre-sales

Before signing the contract, our technician provides customers with various options, including production plans, machine technical consulting, machine selection and other services

Installation

According to the contract, Century will transport the equipment to the installation site designated by the user, and send the after-sales service engineer to install on site.

Service

Prompt and professional service is our promise to customers. We will react in 24 h for weekdays and in 48 h for weekends.

System Automation Soulution

On site planning Solutions Designing Quotation Installation & Follow up

Q: Are you a factory or trading company?

A: We are manufacturer with the export license

Q: Can you do OEM?

A: Customized design is available, OEM and ODM are welcomed

Q: How is the warranty and packing of the machine?

A: ONE YEAR WARRANTY. strong steel cases are used for packing the machine

Q: How to install and training of the machine?

A: Engineers can be sent to you for training, or you can send related person to us for installation and training

Q: Where is your company located? How can I visit there?

A: Our company is located in Weifang City, Shandong Province, China. You can fly to Qingdao or Weifang airport directly. We would arrange the pick-up. All clients, from home or abroad are warmly welcomed