Số mô hình |

Máy cắt die tự động |

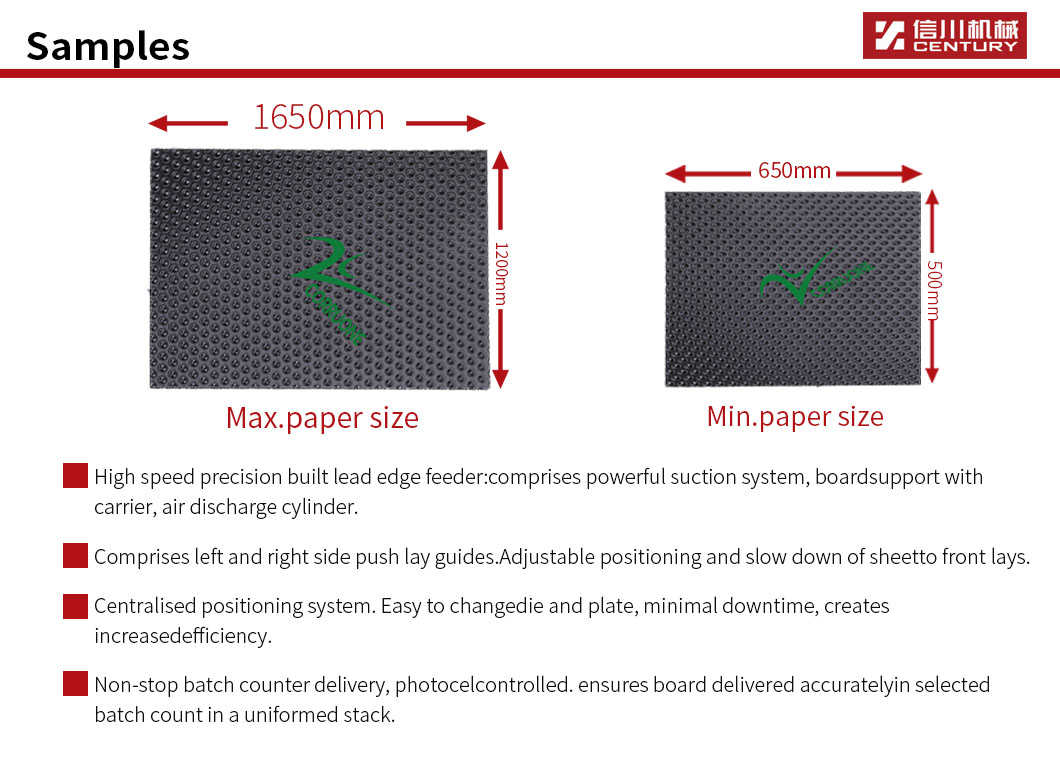

Kích thước giấy tối đa |

1650×1200mm |

Kích thước giấy tối thiểu |

650 x 500mm |

Kích thước cắt tối đa |

1630x 1180mm |

Áp lực cắt tối đa |

450x104n |

Phạm vi vật liệu |

1mm≤Tấm sóng≤9mm |

Chi tiết cắt |

±0,5mm |

Tốc độ Cơ học Tối đa |

5500s/giờ |

Phạm vi Điều chỉnh Áp lực |

10mm |

Kích thước Khung Trong |

47kw |

Kích thước máy (D*R*C) (Bao gồm nền làm việc, bộ cấp liệu trước) |

11200 x 5560 x 2560mm |

Tổng trọng lượng |

≈38t |

Máy cắt die tự động với phần tách giấy sử dụng đầu hút cạnh dẫn/bộ cấp liệng cassete/đầu hút dưới

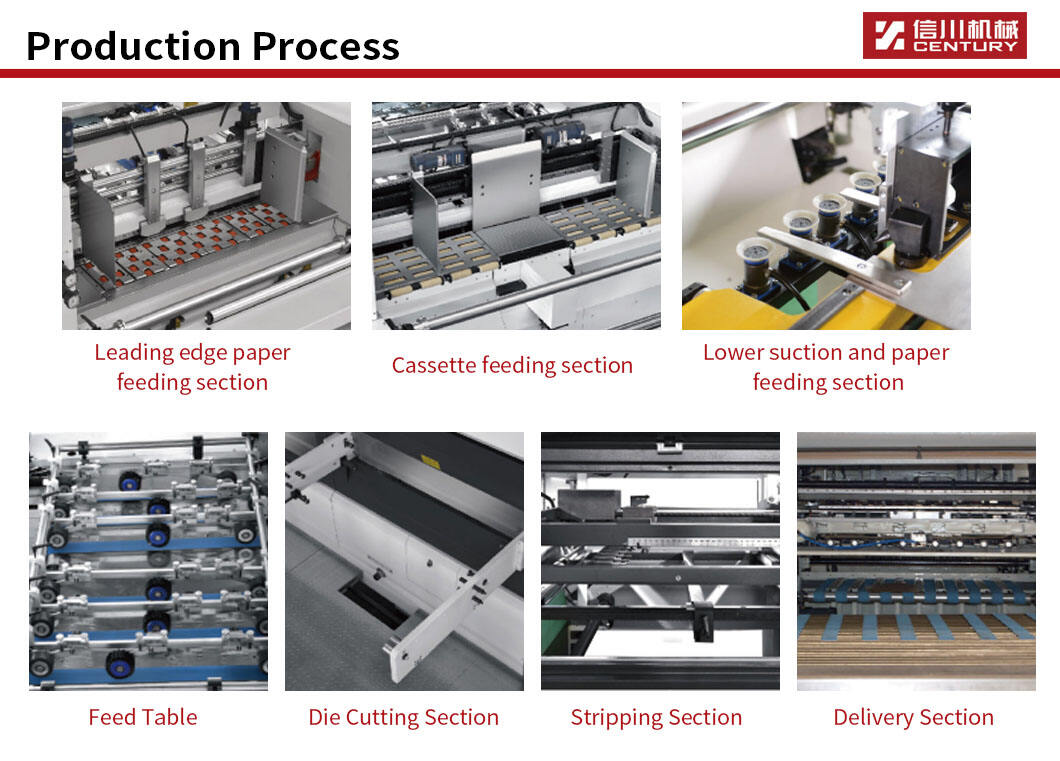

PHẦN 1: Khu vực cấp liệu:

Cơ chế cấp mép chính xác và tốc độ cao. Dấu hiệu đánh dấu lên tấm gần như tối thiểu. Điều chỉnh lưu lượng khí cho các loại vật liệu khác nhau. Diện tích bề mặt hút chân không thay đổi tùy theo kích thước của tấm.

1) Công nghệ bằng sáng chế châu Âu: hệ thống cấp liệu dạng cassette "Vector zero system" Cấp liệu siêu chính xác 0.5mm, ma sát tối thiểu, dịch chuyển tối thiểu, bảo vệ tấm và giải quyết vấn đề đánh dấu. Hiệu quả cao. Các linh kiện cốt lõi được nhập khẩu từ gần đây, không có phụ tùng tiêu hao, hoạt động tuyệt vời trên bảng cong vênh. Xử lý tối thiểu 40-50gsm E, Flute cũng như sóng thông thường.

2) Thiết bị cấp giấy hút từ dưới với độ chính xác cao, hút đáng tin cậy, khu vực hút điều chỉnh được, thiết kế chống xước, bề mặt in được bảo vệ tốt hơn.

PHẦN 2: Khu vực cắt die:

1) Hệ thống khóa khí nén hiệu quả cho việc đuổi. Màn hình điều khiển máy tính với màn hình cảm ứng 3D, cho phép đọc trạng thái máy ngay lập tức và nhận diện lỗi.

PHẦN THỨ 3: Khu vực tách

1) Chuyển động kép với khung tách trên và dưới, khung trên được motor hóa với cần nâng hạ. Bảng nam và nữ được lắp đặt tùy theo công việc mong muốn. Chức năng tách bên phải, trái, sau và nội bộ để tối ưu hóa quá trình tách. Định vị tập trung để giảm thời gian chết trong thiết lập tách.

PHẦN THỨ 4: Khu vực giao hàng

1) Sử dụng hệ thống pa-lét thu giấy, linh hoạt và thoải mái, để tăng hiệu suất làm việc. Sử dụng cảm biến quang điện để đảm bảo quá trình giao hàng mượt mà và ổn định.

2) Hệ thống không ngừng để đảm bảo việc giao giấy ổn định và nhanh chóng. Thiết bị cảm biến quang học hỗ trợ phân loại lô hàng.

CENTURY cam kết sản xuất chuyên nghiệp máy cắt khuôn, và đã phát triển các dòng máy cắt khuôn "Hand Angel" và "FAST". Với chất lượng sản phẩm tốt và dịch vụ sau bán hàng tuyệt vời, CENTURY đã phát triển hơn 3000 khách hàng trong và ngoài nước. Giúp CENTURY và khách hàng cùng phát triển.

Năm 2015, CENTURY đã tiến hành tích hợp sâu hơn công nghệ tiên tiến của thế giới, cung cấp các giải pháp gia công hậu kỳ lý tưởng theo nhu cầu của khách hàng; đồng thời có thể tùy chỉnh dây chuyền thông minh liên động hậu kỳ.

Bán trước

Trước khi ký hợp đồng, kỹ thuật viên của chúng tôi sẽ cung cấp cho khách hàng nhiều lựa chọn khác nhau, bao gồm kế hoạch sản xuất, tư vấn kỹ thuật máy móc, lựa chọn máy và các dịch vụ khác.

Thiết bị

Theo hợp đồng, CENTURY sẽ vận chuyển thiết bị đến địa điểm lắp đặt do người dùng chỉ định, và cử kỹ sư dịch vụ sau bán hàng đến lắp đặt tại chỗ.

Dịch vụ

Dịch vụ nhanh chóng và chuyên nghiệp là lời hứa của chúng tôi đối với khách hàng. Chúng tôi sẽ phản hồi trong vòng 24 giờ vào ngày làm việc và 48 giờ vào cuối tuần.

Giải Pháp Tự Động Hóa Hệ Thống

Quy hoạch hiện trường Giải pháp Thiết kế Báo giá Lắp đặt & Theo dõi

Hỏi: Bạn là nhà máy hay công ty thương mại?

A: Chúng tôi là nhà sản xuất có giấy phép xuất khẩu

Q: Bạn có thể làm OEM không?

A: Thiết kế tùy chỉnh có sẵn, OEM và ODM được chào đón

Q: Bảo hành và đóng gói máy như thế nào?

A: BẢO HÀNH MỘT NĂM. Máy được đóng gói trong các hộp thép chắc chắn

Q: Làm thế nào để lắp đặt và đào tạo sử dụng máy?

A: Kỹ sư có thể được cử đến để đào tạo, hoặc bạn có thể cử người liên quan đến chúng tôi để lắp đặt và đào tạo

Q: Công ty của bạn nằm ở đâu? Tôi có thể đến thăm như thế nào?

A: Công ty chúng tôi nằm tại thành phố Weifang, tỉnh Shandong, Trung Quốc. Bạn có thể bay thẳng đến sân bay Qingdao hoặc Weifang. Chúng tôi sẽ sắp xếp xe đón. Tất cả khách hàng, trong và ngoài nước, đều được chào đón nồng nhiệt

CENTURY

Máy Cắt Khổ Die Tự Động Tay Trái Và Tay Phải Mới MWZ1650G là một sản phẩm cách mạng được mang đến cho bạn bởi thương hiệu đáng tin cậy. Máy cắt khổ die tự động này dành cho giấy chip hộp hoặc hộp carton được thiết kế để đơn giản hóa quá trình cắt die cho cả người vận hành thuận tay trái và tay phải. Với máy này, bạn có thể nhanh chóng và dễ dàng cắt qua giấy, bìa cứng và hộp carton tạo ra các hình dạng chính xác cho nhu cầu kinh doanh của mình. Nó rất phù hợp cho các môi trường thương mại và được thiết kế cho các nhiệm vụ cắt die với khối lượng lớn nhưng vẫn đảm bảo tính đơn giản.

Cực kỳ đa năng, và có nhiều tính năng khiến nó trở thành thiết bị không thể thiếu cho các doanh nghiệp hoạt động trong ngành đóng gói, xuất bản và in ấn. Máy có tốc độ tối đa là mỗi phút và có thể xử lý vật liệu dày lên đến 12mm. Điều này khiến CENTURY trở thành lựa chọn lý tưởng cho nhiều kích thước và hình dạng gói khác nhau.

Cực kỳ thân thiện với người dùng. Nó có giao diện cảm ứng trực quan cho phép bạn điều chỉnh cài đặt một cách dễ dàng, giúp người vận hành nhanh chóng thay đổi cài đặt trong quá trình làm việc và trở lại công việc. Ngoài ra, máy được trang bị hệ thống tự động giảm thiểu chất thải và cấp liệu, khiến quy trình cắt hiệu quả hơn và hoàn toàn không gây phiền phức.

Được thiết kế để bền bỉ, nhờ vào cấu trúc vững chắc và vật liệu chất lượng. Nó có động cơ mạnh mẽ cung cấp hiệu suất cắt ổn định và đáng tin cậy, cho phép máy hoạt động ở mức cao trong nhiều năm. Hơn nữa, nó được thiết kế để tối thiểu hóa thời gian ngừng hoạt động trong quá trình bảo trì, đảm bảo rằng dây chuyền sản xuất của bạn tiếp tục vận hành với ít gián đoạn nhất.

Nổi tiếng về việc sản xuất máy móc chất lượng hàng đầu và thiết bị Cắt Khổ Trái và Phải MWZ1650G Mới không phải là ngoại lệ. Nó được thiết kế với nhu cầu của doanh nghiệp trong tâm trí, cung cấp một giải pháp đáng tin cậy, hiệu quả và thân thiện với người dùng cho tất cả các nhu cầu cắt khuôn của bạn.

Nếu bạn đang tìm kiếm một máy cắt khuôn chất lượng cao, bền bỉ và hiệu quả, Máy Cắt Khổ Trái và Phải MWZ1650G Mới là một lựa chọn tuyệt vời. Với dải tính năng ấn tượng và hiệu suất đáng tin cậy, máy này rất phù hợp cho các doanh nghiệp cần cắt chính xác hàng ngày. Vậy còn chờ gì nữa? Đầu tư vào tương lai của doanh nghiệp bạn và nâng cấp lên MWZ1650G Mới ngay hôm nay.