Die cutting machines are probably the best inventions to get cool shapes and designs! At a basic level, they are speciality tools for people and companies who need to make dozens or thousands of identical cuts. What matter is these CENTURY Die Cutting Machine are save our time and also helps us with painless work so that we can do the task easily. This is why automatic die cutter machine are used in most cases; so you can make stuff faster and with fewer staff. This will help you do more for less which ultimately saves money. The best part about these machines is you do not need to have a creative bone in your body or worry that whatever you come up with will be anything but polished and professional looking.

Productivity is important to all businesses and if your business in crafting, these automatic die cutters would enable you create more product. These machines are specifically designed to reduce the excellent deal of products in much less time. CENTURY Second hand die cutting machine a lot easier when you're trying to make big batches of products quickly. Spending valuable energy on building solitary machines and parts, rather than workers would be a waste of time but you may save that precious work for making pieces with an automatic die cutter. So your business eventually deliver more goods to retailer within less time results in effectively productive and satisfied customer.

This is the necessary work to do in solving difficult problems for those who wish to innovate ways of creating at their place of employment and within business. Instead of having to hand cut your items out, an automated die cutting machine does the work for you in no time at all. From start to end these machines act like a slicer in cutting the food. You can load the material, process CENTURY Semi automatic die cutting machine and even cut on size themselves! That is a convenient box you check off and move onto more important things that drive your business forward.

Businesses that use automatic die cutting benefit from it in a number of ways. Firstly, you will see that they are really simple to make use of. Even a newbee can learn, they are dead easy to control. These features can provide even stiff cutting for machines with adjustable speed and high precision. They are beasts designed for high-volume manufacturing (less labor). It furthermore enables faster production while ensuring reduced errors.

It truly can revolutionize the way in which you CREATE from your die cutting machine. These will enables them to reduce the processing time they are taking so that it would take correct information. It also makes all of the mess, cutting materials easier and I could let for a higher accuracy and consistent results. They are also intelligent as they can mould themselves to certain materials without getting a completely changeover. That way you can avoid long breaks and keep from damaging the current state of operations. And the use of die-cutting automation also ensures minimization of errors and defects, which in turn means that your products are better.

Automatic die cutting machine company is dedicated to providing excellent after-sales services. It has a comprehensive system to provide expert technical assistance, maintenance, and customer service and also resolve all issues. The company is a leader in RD capacity and is China's only "Flatbed Technology RD Centre" that has been recognized by the Shandong Packaging and Printing Association. Continuously investing in RD funds, carrying out technological innovations and product enhancements and upgrades, we are able to supply clients with high-end technological solutions and products.

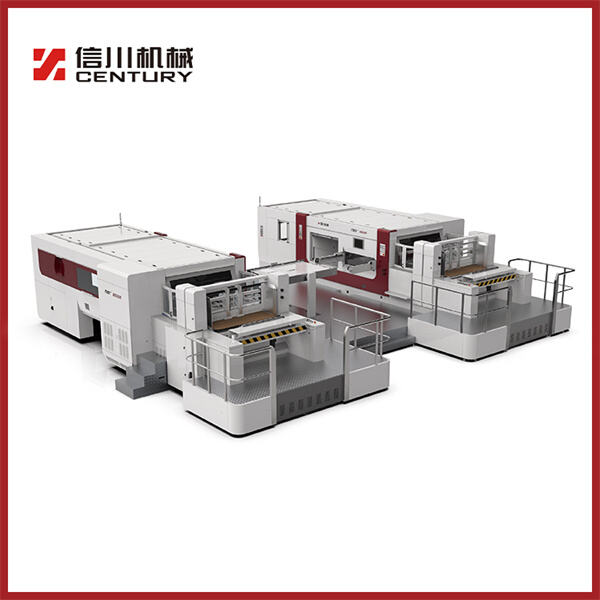

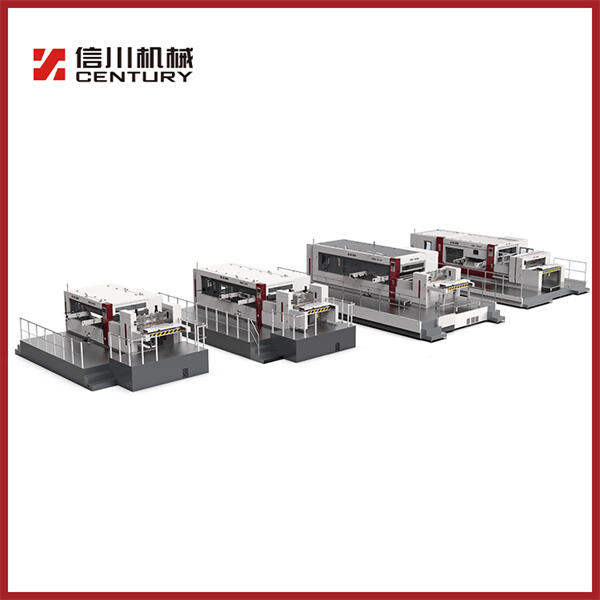

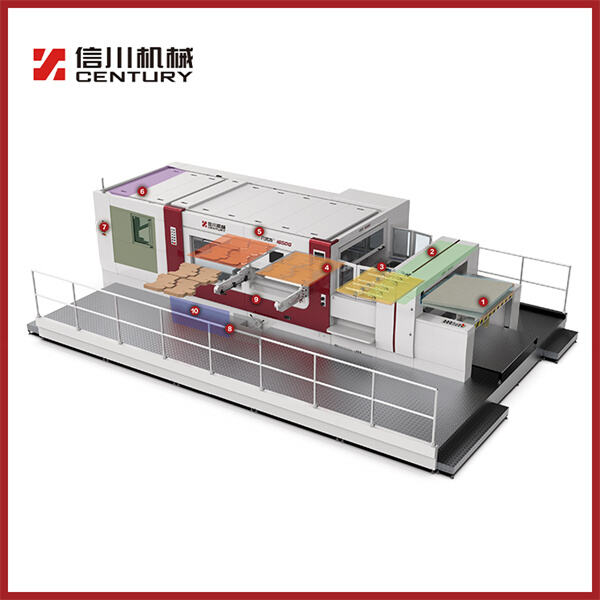

The flatbed die cutting machine of CENTURY is able to cut corrugated papers, but also other materials. It has a wide range of applications that can meet the requirements of a variety of customers. To ensure precision in die cutting, the equipment uses high-quality materials and the latest technology, which includes high-strength tooth and precise paper gripping mechanism. Die-cutting pressures are consistent and precise as well as there is less plate reprinting. Certain models are capable of reaching an maximum speed of 7,500 sheets per hour. It has high efficiency of operation, and is able to be combined by pre-press equipment for improved the overall efficiency of production. The Automatic die cutting machine front-edge paper feeding fully automated, intelligent die cutting machine has achieved intelligent and automated technological breakthroughs in the production process, as well as cardboard quality and safety assurance which greatly improves the efficiency of orders change.

We've been continually improving and innovating our products, and have released a Automatic die cutting machine of distinctive products. For example, the cassette paper feeding machine makes use of vector "zero" point motion to feed paper with no friction and no displacement, which fundamentally solves the problem of scratches on the printed surface. the left and right push gauge of the bridge component is able to meet the needs of different printing registrations, and assures precise positioning of the cardboard. There is a wide range of model options, including 930 1050, 1160 1300 1450, 1620, and so on. for semi-automatic products and 1050,1080 1450, 1650 and so on. Fully automatic machines can be modified to meet the requirements of customers. CENTURY Machinery flatbed die-cutting machines are cheaper than imported products. The quality and performance of the product is able to meet the demands of the customer, in addition to being cost-effective.

Shandong Century Machinery Co., Ltd. was founded in Automatic die cutting machine. It's a ISO9001 quality management system that has been certified as well as a CE certified business. It is a high-tech regional enterprise and a national "little giant" business. It is a company with a lot of acclaim and respect in the field. The company currently has more than 50 expert scientists and a seasoned technical RD and production team to ensure the high-quality and performance of its products. The products offered by the company are extensively sold across 29 provinces, cities and autonomous regions of China and exported to more than 60 countries, including the United Kingdom. It has a wide customer base as well as a market, and its products have been acknowledged by both foreign and domestic customers.