Corrugated die cutters are the special bodies which have been built for slice and condition packages made from corrugated frustrated cardboard. We use these guys to help make our boxes with precision and efficient. This CENTURY Second hand die cutting machine allows a corrugated die cutter machine to efficiently make boxes that offer high quality, while taking up little time. Even if you are a complete new start up or probably have big fortune 500 clients but do not yet use corrugated board, I am convinced that there is still something for each of you in the next three points showcasing why to get die cutters

Cube band die cutting machineThe cube nk and nk is have digital read out for fast accurate changes and fastest production times This way they are able to quickly produce in boxes, which is excellent to satisfy customer requirements. Considering that the blades are really sharp, these machines can easily work with any and possibly even multiple layers of thick cardboard at a time. So that they can create boxes in different shapes and sizes without wasting materials. The machine is capable of measuring each box to ensure it is the proper size, not only saving you time but also helping reduce waste. This is crucial because wasted materials translates to money down the drain and production downtime.

A corrugated die cutter is a good choice for your business. The biggest reason for is it that help you to produce a quality of boxes in short time. Once businesses can create boxes at the speed required, they are more able to deliver what their customers want and compete with other companies in that sector. In a world in which customers are king, this is all the more essential. Additionally, it could help save you money on material costs and amount of waste when it comes to making the box. In the grand scheme of things, this investment can save you a lot.

Corrugated die cutter is much more efficient mainly because it carries out a number of tasks automatically and thus, this can help in streamlining the process involved while making boxes. This CENTURY Die Cutting Machine helps your employees save their time and energy which means they can work on other productive jobs that need them. It is capable of producing a large number of boxes at you desired length in short time. The fastest time to market and the most flexible delivery system for your customers in all sizes. It helps create less downtime in your business by automating the box production process with a corrugated die cutter.

One way to really streamline your box production is by using a corrugated die cutter. This allows each box to be cut at exactly the right size and making less waste and higher quality over all. If boxes are made correctly, they not only look better- but will perform better too! Besides, the machine can make multiple boxes quicker than manually creating one box. That means you can make more boxes in less time without compromising on the quality – a win-win for your business.

Irvine, —From the very top down to every corner of a package as well-the corrugated die cutting technology — Everything is changing in how boxes are really created. This CENTURY Products makes the manufacturing of boxes faster, easier and more efficient. This change in the style of working is helping business to be more agile and aligned with customer needs irrespective of their size. This new technology will allow you to greatly improve how your boxes are made, and keep you competitive in your industry by getting a corrugated die cutter.

The company focuses on after-sales support and has set up an entire after-sales system that can meet customer needs in a Corrugated die cutter, and provide customers with professional and efficient technical support and maintenance services. They also solve customers' worries. The company is the only "Flatbed Die-cutting Machine RD Centre" in China recognized by the China Packaging Federation and the "Shandong Flatbed Technology RD Center" awarded by the Shandong Packaging and Printing Association with strong RD capabilities. Constantly investing in RD funds, implementing technological advancements and product improvements and upgrades, we are able to supply customers with cutting-edge technology and products.

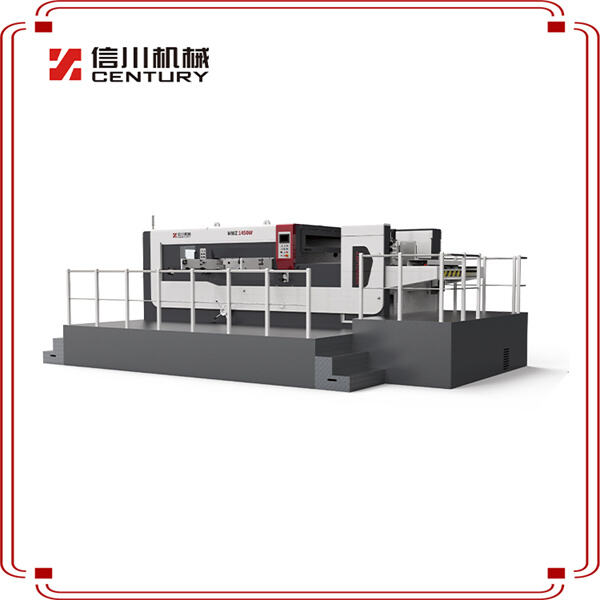

Shandong Century Machinery Co., Ltd. was established in 2008. It is an ISO9001 quality management system certified and CE certified enterprise. It is a state-of-the-art provincial company as well as an specialized national "Corrugated die cutter" company. It has a high degree of recognition and reputation in the market. It is home to more than fifty skilled scientists, as well as a strong RD department and production team. This guarantees the highest quality and performance. The products offered by the company are sold well in 29 provinces, cities and autonomous regions in China as well as exported to over 60 countries, including the United Kingdom. It has a wide customer base and market base and its products have been accepted by both domestic and international customers.

The flatbed die cutting machine of CENTURY is able to cut corrugated papers, but also other materials. It has a wide range of applications that can meet the requirements of a variety of customers. To ensure precision in die cutting, the equipment uses high-quality materials and the latest technology, which includes high-strength tooth and precise paper gripping mechanism. Die-cutting pressures are consistent and precise as well as there is less plate reprinting. Certain models are capable of reaching an maximum speed of 7,500 sheets per hour. It has high efficiency of operation, and is able to be combined by pre-press equipment for improved the overall efficiency of production. The Corrugated die cutter front-edge paper feeding fully automated, intelligent die cutting machine has achieved intelligent and automated technological breakthroughs in the production process, as well as cardboard quality and safety assurance which greatly improves the efficiency of orders change.

We've been continually improving and innovating our products, and have released a range of Corrugated die cutter products. The cassette-type feed machine employs, for instance, a the vector "zero point" motion to feed the paper using zero friction and with no displacement. This is a solution to the scratching problem on the surface of the print. The range of products includes 930, 1050, 1150, 1300, 1450, 1620 etc. to semi-automatic equipment and 1050,1080, 1450, 1650, etc. for fully automatic products, which can meet the scale of production and process requirements of different customers. CENTURY Machinery flatbed die-cutting machines cost less than imported machines. The quality and performance of the product is able to meet the demands of the customer, in addition to being cost-effective.