A die cutting machine is a massive device that can reduce shapes into CENTURY cardboard or another substance. It may not sound super thrilling out of the gate, but it can be a big WIN for your factory. Among other things – for example, you can sell faster than lightning. And it will do the hard work for you, instead of cutting each and every piece by hand which is obviously time-consuming. This means that you can develop more products, faster…far better for the business. Something else that is wonderful about using a die cutting machine, and why I prefer to use my Big Shot instead of dies for simple shapes., is because it can cut very precise cuts. This machine has sharp blades to accurately and smoothly cut the material. Note that these blades are made to slice leather super fine, so you can make an exact product of sizes and shapes. Which is really crucial if you want your products to be pretty and fit together nicely in a way which makes life easy for customers.

Your good-looking products will also work better when they have perfect cuts. Try to think about solving a puzzle, if the pieces are not properly shaped. It would be frustrating. Well, same for all the products which you will create. If everything meshes cleanly and looks smooth, you will make your clients even happier which in return makes them more prone to future orders from you. Act of purchasing something which benefits your factory is known as investing. When you spend money on something, the result is you are investing in that thing because (up to certain point) with your purchase ——you think it can give PROMISED value later. It might be worth it for your factory to consider purchasing a die cutting machine. This could save you a lot of money in the future. The initial cost to buy the machine is very high, but in return it will save you money on manpower which you have to use for cutting pieces by hand. You save this with a long way.

A die cutting machine can help us buy better products. Your goods will look better, but more importantly to you as a customer this article is that it be easier and build the machine time produces perfect cuts. The product speaks for itself; hence customers will love what they buy. They will be the first to share their contentment with your product and become returning customers.

By definition, flexibility involves the capability of being changeable in a way that could be done swiftly and effortlessly. You can be more versatile in making your products with a die cutting machine. it indicates that you can change the size or shape of your creations as needed. If you get a new order for another design of products then the machine can be changeover to that product designing in minimum time with fewer efforts. Design modifications to the die mold will allow a new product to be created almost instantly. By so doing, you remain a proactive entity that is always one step ahead of other factories and retain the satisfaction (and continued patronage) of your customers.

Applications - what you are going to use the machine for. It is necessary to select the appropriate die cutting machine suitable for your needs. Translating this to a CNC machine would be picking one that has the capability of cutting whatever materials you hope/wish/planning/using (whether they are cardboard or plastic and then possibly in different shapes/sizes. You also have to desire a durable and reliable machine that is very easy to use. It is important that we look for a machine which will not have frequent breakdowns or will also become difficult to use.

Shandong Century Machinery Co., Ltd. was founded in 2008. The company is CE-certified and ISO9001 certified. It is also a high-tech company in the province and one of the nation's specialized "little giant" company. It enjoys a high level of respect and recognition within the market. The company has over 50 skilled scientific researchers as well as a robust technical RD and production team to ensure the quality and efficiency of their products. The company's products are sold effectively in Corrugated die cutting machine provinces, municipalities, and autonomous regions of China, and exported to over 60 countries such as the United Kingdom, Turkey, Japan and many more. The company has a huge customer and market base. The products are appreciated by both international and domestic customers.

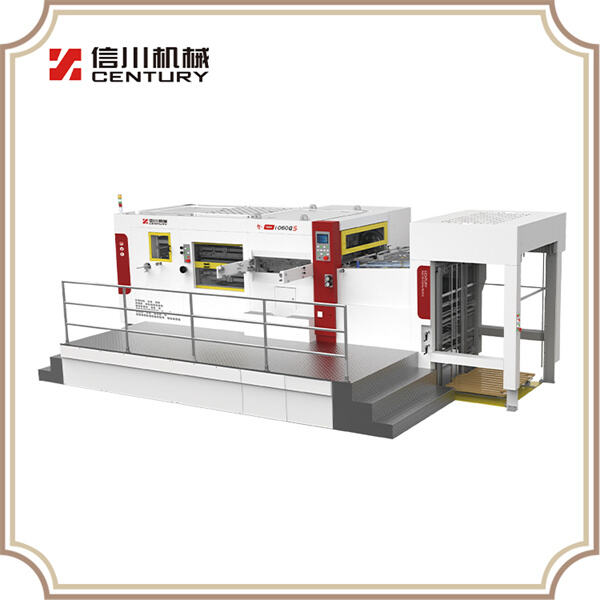

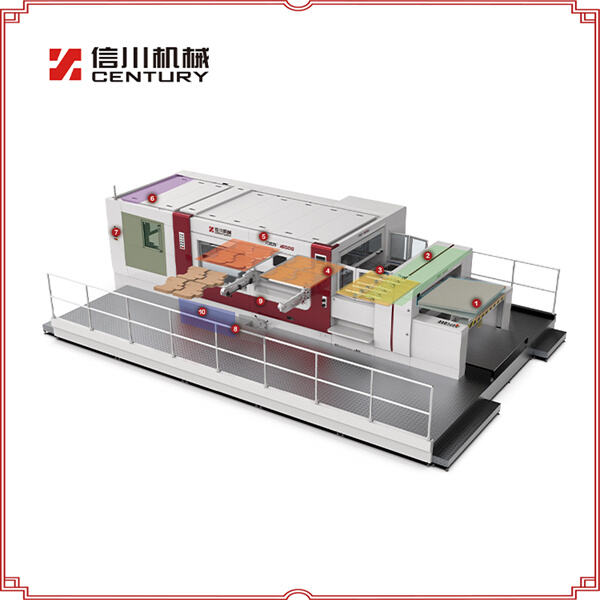

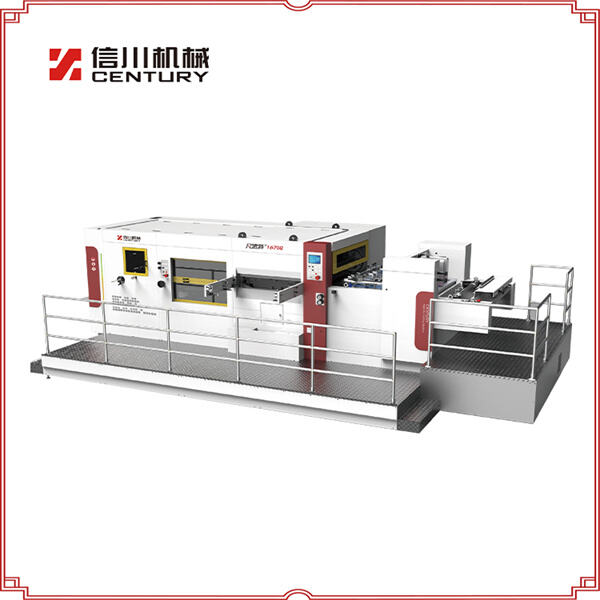

The flatbed die-cutting machine from CENTURY is able to die-cut not just Corrugated die cutting machine however, it can also cut cardboard and other materials. It has a wide range of applications and can meet the needs of different customers. The equipment is built with the latest technology and high-quality components, such as high-strength teeth and precise paper gripping mechanisms which ensures the die-cutting accuracy of paper. The pressure used to cut paper is uniform, with less plate re-printing and is precise and durable. Some models can attain 7500 sheets per hour, and have excellent efficiency. It can be matched with pre-press equipment to improve the overall efficiency of production. The new front-edge paper feeding fully automatic intelligent die-cutting machine has achieved intelligent and automated technological advances in production efficiency, the quality of cardboard, and safety guarantees significantly improving the efficiency of production for order change.

We've been continually improving and innovating our products, and have released a Corrugated die cutting machine of distinctive products. For example, the cassette paper feeding machine makes use of vector "zero" point motion to feed paper with no friction and no displacement, which fundamentally solves the problem of scratches on the printed surface. the left and right push gauge of the bridge component is able to meet the needs of different printing registrations, and assures precise positioning of the cardboard. There is a wide range of model options, including 930 1050, 1160 1300 1450, 1620, and so on. for semi-automatic products and 1050,1080 1450, 1650 and so on. Fully automatic machines can be modified to meet the requirements of customers. CENTURY Machinery flatbed die-cutting machines are cheaper than imported products. The quality and performance of the product is able to meet the demands of the customer, in addition to being cost-effective.

The company focuses on after-sales support and has set up an entire after-sales system that can meet customer needs in a Corrugated die cutting machine, and provide customers with professional and efficient technical support and maintenance services. They also solve customers' worries. The company is the only "Flatbed Die-cutting Machine RD Centre" in China recognized by the China Packaging Federation and the "Shandong Flatbed Technology RD Center" awarded by the Shandong Packaging and Printing Association with strong RD capabilities. Constantly investing in RD funds, implementing technological advancements and product improvements and upgrades, we are able to supply customers with cutting-edge technology and products.