EVER seen that machine they use to cut cardboard with finesse? A cardboard cutting machine does just that. Cardboard is a generic term for heavy-duty paper-based products having greater thickness and superior durability or other specific mechanical attributes. It is imperative as it safeguards the items during forwarding to customers.

Like, some time back before you could hand cut your own cardboard boxes. This was not easy at all, same with the CENTURY Semi automatic die cutting machine. It was a lot of work and time to find the boxes which were cut in right size. With the cardboard cutting machine, the process of cutting cardboard to slits is now already lightning quick and effortless than ever.

In this way, a cardboard cutting machine as well as CENTURY Automatic die cutting machine is such an invention that makes factories and warehouses able to work with more speed and simultaneously. It merely orders the machine to cut a box in their specified size and everything is done. In this way, the workers can take care of other work if a machine is handling all cuts.

Businesses which dispatch items to customers must have good packaging. When a business ships products, it is paramount that the items should not only reach its destination but are also safe and secured during transport. Cardboard boxes are a decent form of protection, but they will need to be trimmed down before you can use them. For that, enter the cardboard cutting machine.

In the past, companies had to hire skilled workers who could manually cut boxes quickly and accurately before the cardboard cutting machine was invented, also the CPU Intelligent Packaging Line. This was a big challenge and takes quite some time to learn. The Machine The time and money required by the factories to do it automatically is much less so Aufheben Gmbhis of late now.

Then insert the cardboard cutting machine, so fast, just like the CENTURY Second hand die cutting machine. It produces hundreds of boxes per hour (up to the size and complexity). That is how businesses can complete orders much faster and thus accept more work. After all — who would not love receiving their products in minimal time?

Since the material is used up more effectively with custom box sizes, less boxes wind up in landfills. This is great for our planet. Similarly, as the cutting process is performed almost instantly it minimises energy consumption. This effectively reduce the cost of energy for the businesses who use this machine.

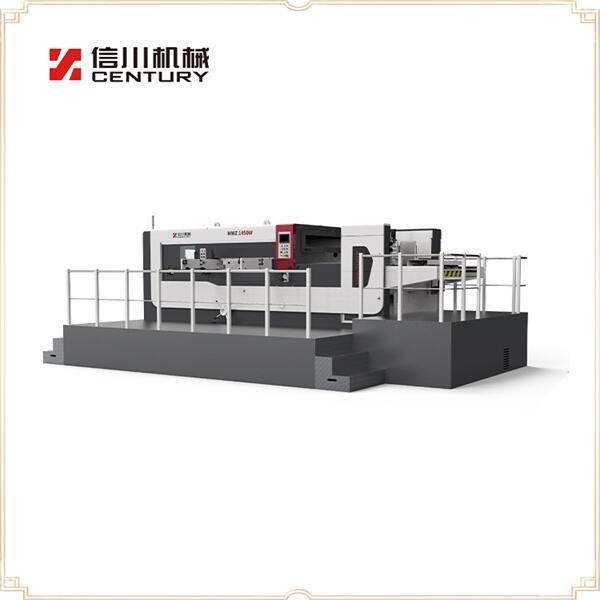

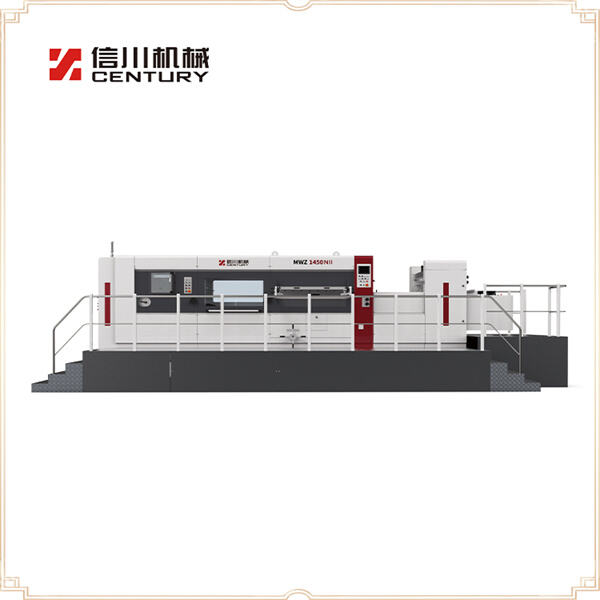

Shandong Century Machinery Co., Ltd. was established in 2008. The enterprise is CE-certified and ISO9001 certified. It is a state-of-the-art regional enterprise and a specialized national "little giant" company. It enjoys a high level of recognition and a good reputation within the business. The company has more than 50 highly skilled scientific researchers and a strong technical RD and production team to ensure the quality and efficiency of their products. The company's products are sold well in 29 provinces, municipalities, and autonomous regions of China and exported to more than 60 countries such as the United Kingdom, Turkey, Japan and more. The company has a vast customer base and market base and its products are accepted by both domestic and Corrugated paper cutting machine.

We've been constantly developing and improving our products and have released a range of distinct products. For example, the cassette-type paper feeding machine uses vector "Corrugated paper cutting machine" point motions to feed paper, with no friction and no displacement, which solves the problem of scratches on the printed surface; the push left and right gauge method of the bridge piece meets the requirements of different printing registrations, and assures precise positioning of the cardboard. There is a wide range of products models, such as 930, 1050, 1160, 1300, 1450, 1620, and so on. for semi-automatic products and 1050, 1080, 1450, 1650, and so on. for fully automatic products and can be adapted to the production capacity and process needs of various customers. When compared to imported equipment, CENTURY Machinery's flatbed die-cutting machine has clear advantages in terms of price. The performance and quality of the product is able to meet the demands of the customer, in addition to being cost-effective.

The flatbed Corrugated paper cutting machine of CENTURY is able to cut corrugated papers, but other materials. It is able to be utilized for a range of purposes and meet the demands of different clients. It is equipped with advanced technology and top-quality materials like high-strength teeth and precise mechanisms for gripping paper, to ensure the die-cutting accuracy of paper. Die-cutting pressures are consistent and precise, and there is less need to reprint plates. Some models can reach the maximum speed of 7,500 sheets per hour, with excellent efficiency. It can be matched with pre-press equipment to enhance overall production efficiency. The latest front-edge paper-feeding completely automated intelligent die cutting machine is an technological advancement that has been fully developed to be intelligently automated and improve production efficiency in terms of quality, cardboard production and security.

The company is committed to Corrugated paper cutting machine outstanding after-sales service. It has a comprehensive system that can provide professional technical assistance, maintenance and customer service and resolve any issues. The company is the only "Flatbed Die-cutting Machine RD Centre" in China recognized by the China Packaging Federation and the "Shandong Flatbed Technology RD Center" awarded by the Shandong Packaging and Printing Association, and has robust RD capabilities. We can offer our clients advanced products and solutions through continuous investment in RD as well as conducting technological innovation and improving the quality of our products.