Hello, young readers. Hello Are you aware of die cutting press machines? Kind of like this awesome thingy that factories used to speed the process up. Here, in this article we are going to talk about how the die cutting press is saving time as well cost of factories. There are some incredible machines out there that have a huge part to play in making just about everything.

The factory use this when they want to make a lot of the same thing is done in die cutting presses such as Second hand die cutting machine. These machines are simply amazing in a way that they can make shapes out of every possible stuff, from paper to plastic and fabric. Just imagine the trouble you would go through having to manually cut this shape over and over. This would take incredibly long, and may well be exhausting. The best part of the die cutting press is it helps to cut a lot no of pieces together at once, so these kinds are using for labors who make goods in bulk.

No liability will be taken for usage of any information provided in this email, at a users own risk. Processes that require cutting: Die and Cutter. The Die cutting press is the machine used to cut with die. Dies are the equivalent of cookie cutters, but in shapes that factory wants to churn out, same with the Semi automatic die cutting machine. So that when the machine cuts predestined, it can cut many of those shapes at once — think cookie cutter in roll-out dough. This is why factories are able to produce objects quickly and effectively.

Die cutting Presses: These presses are wonderful for manufacturing purposes because this will allow the users to save plenty of time and money, along with Automatic die cutting machine. Since these plants are quite heavy so on production factories as well as in use of this machines slow many things can be made. Because they get to sell more things in less time, and good for business. The faster it is and comes out, the more you can sale of course. They also sell people, and that is much more expensive than carving material off by hand. So you have to pay more for the cutting job, but it is performed by workers.

Except for the fact that die cutting presses will save you a lot of money by providing accurate results. This means that each part will be the same from machine to machine, as well as CPU Intelligent Packaging Line. This is important because it will ensure every small part aligns. It saves them from mistakes that can be so costly to correct. Oh man, what if you had to begin anew on a job because all of the parts just weren't snapping in there like they should — that would be time (and material) lost.

Why die cutting presses are so important in manufacturing, same with the Honeycomb panel, they can create basic shapes or be programmed to cut out intricate designs. It is applied to paper, use of them as name badge pouches This enables in the ease of carrying it and plastic films Nevertheless the laminating pictures can also be used on fabrics And this makes them common among various factories.

Shandong Century Machinery Co., Ltd. was established in 2008. It's an ISO9001 quality management system certified and CE certified business. It's also a Die cutting press company in the province and it is a national-specific "little giant" company. It has a high degree of acclaim and respect in the industry. It has more than fifty skilled scientists, as well as a strong production and RD team. This ensures the quality and effectiveness. The company's products are distributed efficiently in 29 provinces and municipalities and autonomous regions in China and exported to over 60 countries such as the United Kingdom, Turkey, Japan and more. The company has a substantial customer and market base. The company's products are highly regarded by both international and domestic customers.

The company is dedicated to providing top after-sales support. It has a comprehensive system for providing professional technical assistance, maintenance and customer support and also resolve any problems. It is the only "Flatbed Die-cutting Machine RD Centre" in Die cutting press awarded by the China Packaging Federation and the "Shandong Flatbed Technology RD Center" named by the Shandong Packaging and Printing Association and boasts an impressive RD capability. Constantly investing in RD funds, carrying out technological innovations and product enhancements We can supply customers with cutting-edge technological solutions and products.

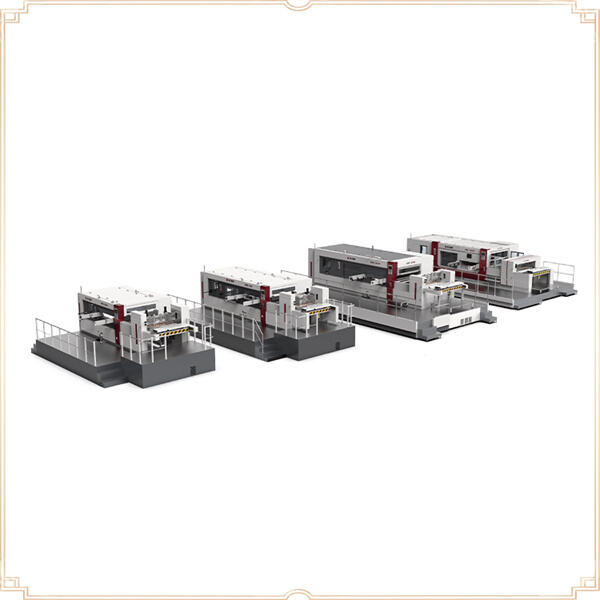

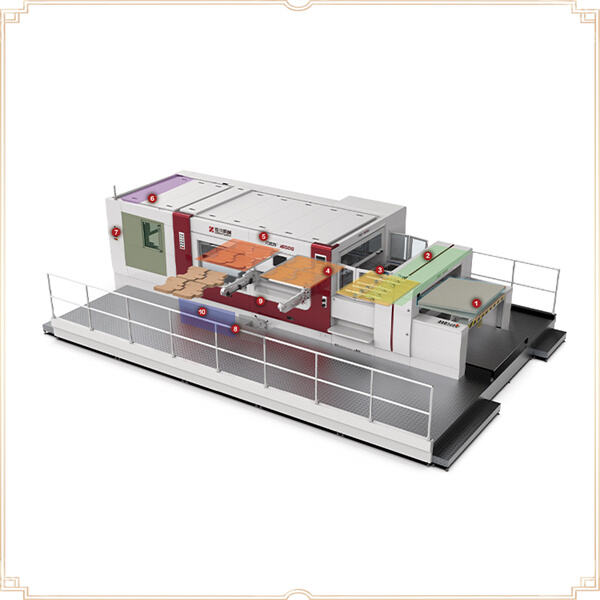

We've been constantly developing and improving our products and have released a range of distinct products. For example, the cassette-type paper feeding machine uses vector "Die cutting press" point motions to feed paper, with no friction and no displacement, which solves the problem of scratches on the printed surface; the push left and right gauge method of the bridge piece meets the requirements of different printing registrations, and assures precise positioning of the cardboard. There is a wide range of products models, such as 930, 1050, 1160, 1300, 1450, 1620, and so on. for semi-automatic products and 1050, 1080, 1450, 1650, and so on. for fully automatic products and can be adapted to the production capacity and process needs of various customers. When compared to imported equipment, CENTURY Machinery's flatbed die-cutting machine has clear advantages in terms of price. The performance and quality of the product is able to meet the demands of the customer, in addition to being cost-effective.

The Die cutting press die-cutting machine from CENTURY can cut not just corrugated paper but also cardboard as well as other materials. It is able to be used for a variety of purposes and meet the requirements of various clients. The equipment uses advanced technology and high-quality components that include high-strength steel teeth and precise mechanisms for gripping paper, to ensure the precision of the die-cutting process for the paper. Die-cutting pressures are precise and uniform and the result is less reprinting of plates. Some models have a maximum speed of 7,500 sheets an hour. They're extremely efficient and can be combined in conjunction with pre-press equipment to improve efficiency of production. The new front-edge paper feeding fully automated intelligent die-cutting machine has made intelligent and automated technological innovations regarding production efficiency, quality of the quality of cardboard, and safety guarantees significantly improving the production efficiency of order changes.