Thick materials like leather, foam or rubber are harder to cut and need a lot of work. This whole process is made simpler and faster with the help of a platen die cutting machine. The drill machine Dates Again to ancient Egypt which uses a point and stick technique, however, we know that Thanks for this art of welding Service, A Die-Cutting device dates back at the 19 Th Century today. Each time these two devices may possibly appear antithetical; they are in reality similar from the history. CENTURY Automatic die cutting machine end up staying invaluable if revolutionary on substance. Just enjoy every electric one more cutter includes distinct business benefits but fundamentally each category definitely can help all procedure producers even though sourcing their chemical by simply clipping stuff directly into silhouette necessary. Platen die cutting machines are one of the best tools for turning your product into a unique shape when extra consideration is needed. They are also multi material cutters which means they can cut through more than one layer of materials at a time. Not only does this save you a ton of time, but its way less effort. Whether you are creating fashionable leather wallets or packaging foam inserts, making rubber machine parts and other accessories — this machine will get the job done quickly as well efficiently.

Platen die cutting machines are great because they can achieve so much. Hosting various tasks as they can be very helpful for your production requirements. You will need different types of cutting dies for this purpose to create unique shapes and designs on your products. A cutting die is a metal plate with sharp edges that are made to cut into the material. After you identify the ideal die for your product, it is simple to quickly produce many identical shapes. Platen Die Cutting Machines: These platen die cutting machines cut many different materials such as paper, fabric, leather, foam or rubber. In other words, you can customize your assembly line the way it best suits your need. No matter if you're making custom packaging, furniture upholstery or fun toys; this machine can be useful when crafting something that is one-of-a-kind and separates from the rest of the market.

These machines are incredibly precise. Instead, they permit you to create clean cuts with crisp corners and lots of details. This CENTURY Semi automatic die cutting machine precision makes sure each cut is to the specification of your design, therefore you get exactly what was intended without imperfection from machine or human trek error. In addition, the technology employed in platen die cutting machines keeps its blade sharp during actual-cut. This helps minimize the risk of tears or damage to materials that less accurate cutting techniques can sometimes cause.

Die cutting is a great benefit for most companies, and if done as an automated die cutting it will improve your production process. Using a platen die cutting machine allows businesses to automate the overwhelming process of material cuts, saving both time and money. We upgraded these cutting cells with automation to reduce labour and prevent the cutting process being a limiting factor in our production line, as some manual processes can be slow or inconsistent.

Using an automated platen die cutting machine, you can create a large quantity of the same shapes and designs in the shortest time. With this level of efficiency you will be processing the large orders in a small time quantity thereby enhancing your total productivity. CENTURY Second hand die cutting machine also frees up your staff to attend other duties instead of having them running the machine for longer periods so, in a way it increases productivity and ultimately profit.

The company is attentive to the after-sales service and has created an entire after-sales system that is able to respond to customer needs in a timely manner, and provide customers with skilled and Platen die cutting machine and maintenance services, and solve customers' worries. The company has a strong RD capacity and is the only Chinese "Flatbed Technology RD Center", awarded by the Shandong Packaging and Printing Association. Constantly investing in RD funds, implementing technological innovation and product upgrades We can supply customers with the latest technology and products.

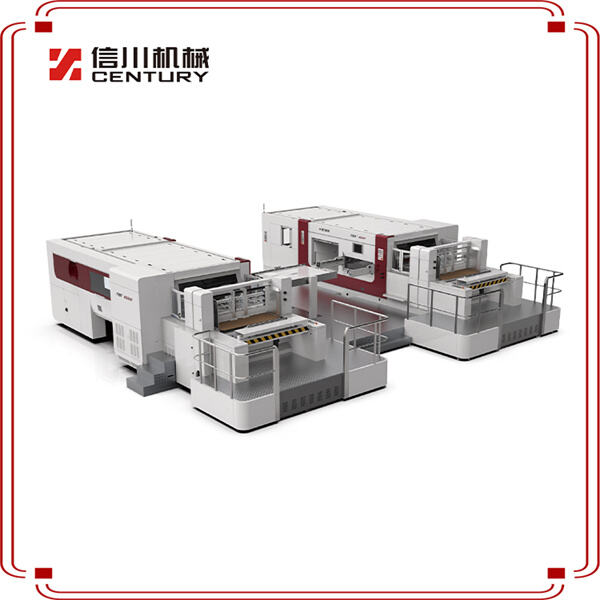

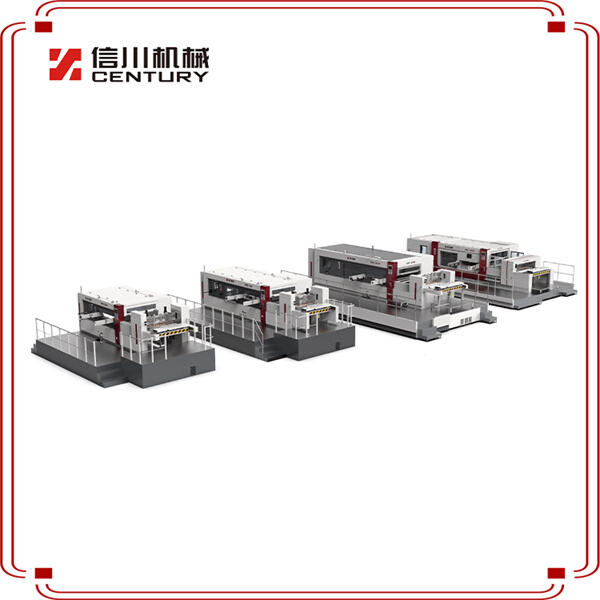

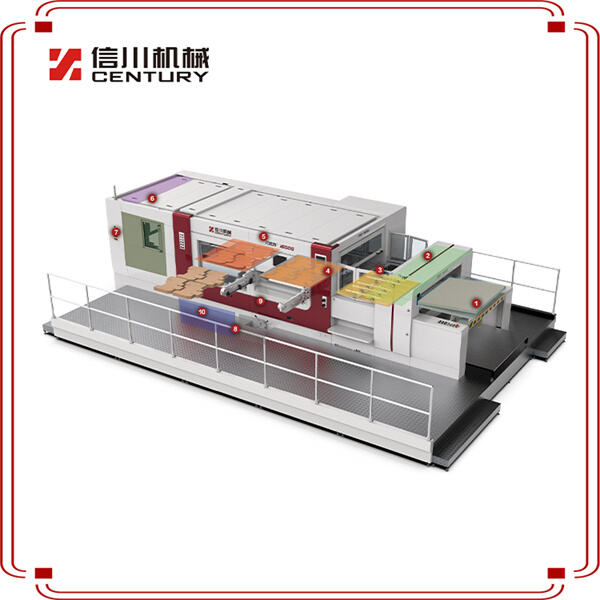

The flatbed die cutting machine from CENTURY is able to cut corrugated papers, but other materials. It can be utilized for a range of purposes and meet the needs of many clients. To ensure precision in die cutting this equipment is constructed with high-quality materials and modern technology, including high-strength tooth and a precise mechanism for gripping paper. The pressure used to cut paper is uniform which means that there is less Platen die cutting machine of plates and is also precise and long-lasting. Certain models can achieve an maximum speed of 7,500 sheets per hour, with high efficiency of operation, and can be paired with pre-press equipment to enhance the overall efficiency of production. The latest front-edge paper-feeding completely automated intelligent cutting die is a breakthrough technological advancement that has been fully designed to be automated and has improved production efficiency as well as the quality of cardboard used and security.

Shandong Century Machinery Co., Ltd. was founded in 2008. It is CE-certified and Platen die cutting machine certified. It is a state-of-the-art provincial company as well as a specialized nationwide "little giant" business. It has a good level of recognition and repute in the business. The company has more than 50 professional scientific researchers and a strong RD and production staff to ensure the high-quality and efficiency of their products. The products of the company are sold well in 29 provinces, municipalities, and autonomous regions of China, and exported to more than 60 countries including the United Kingdom, Turkey, Japan, etc. The company has a large market and customer base. The products of the company are admired by both international and domestic customers.

We've been constantly developing and improving our products and have released a range of distinct products. For example, the cassette-type paper feeding machine uses vector "Platen die cutting machine" point motions to feed paper, with no friction and no displacement, which solves the problem of scratches on the printed surface; the push left and right gauge method of the bridge piece meets the requirements of different printing registrations, and assures precise positioning of the cardboard. There is a wide range of products models, such as 930, 1050, 1160, 1300, 1450, 1620, and so on. for semi-automatic products and 1050, 1080, 1450, 1650, and so on. for fully automatic products and can be adapted to the production capacity and process needs of various customers. When compared to imported equipment, CENTURY Machinery's flatbed die-cutting machine has clear advantages in terms of price. The performance and quality of the product is able to meet the demands of the customer, in addition to being cost-effective.