The reason for this is the laser cutting technology used in these machines, which has been adapted to work with cardboard. We produce carton in different shapes and sizes as per required for box-making. A die is the pattern or mold that helps shape the way a piece of cardboard can be cut. The CENTURY Automatic die cutting machine makes sure that the cardboard is aligned with the die and pressed down to perfect cut out the shape. In the time that has passed, cutting machines for carton box evolved immensely. Machines today come with intelligent software which makes creating (and cutting) difficult or intricate designs super simple. Adding a new technology, this fast and swift box cutting has been extremely beneficial to large scale business enterprises who require numerous boxes.

The laser cutter is one of my favorite cutting machines. With a high-powered laser beam the cut-time is minimal for cardboard on most professional models of laser cutter. When an image is detected and the machine replicates that design, it does so to perfectly cut a box in the correct measurements. Using this technology, companies are able to make the box for their products that fits perfectly.. when it matters most while shipping. The advent of carton box cutting machines has revolutionised the way boxes are produced. Previously, cutting of boxes was a manual process which would require lot time and effort. This required individual pieces to be hand measured and then cut, a slow as well tiring process. These machines can offer the ability to make boxes not just quicker, but much more effortlessly.

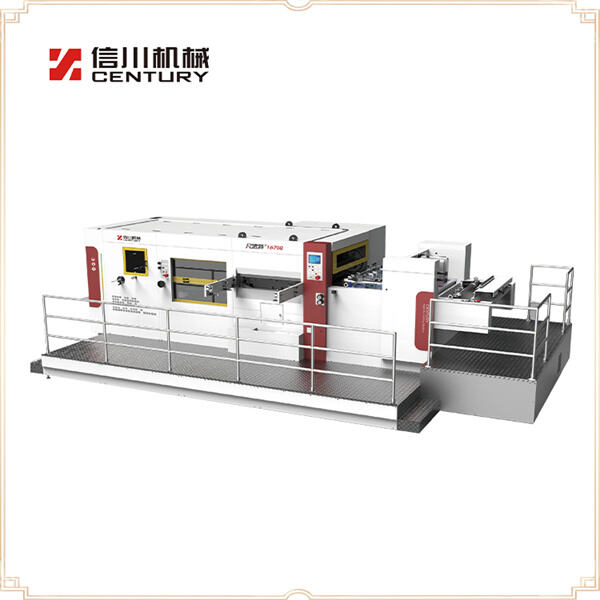

Cutting machines actually produce nicer boxes too. Hand-cut boxes can also be uneven and weak. The boxes can become an issue if heavy items need to be carried. However, when creating with cutting machines boxes are produced in crisp lines and solid edges. This CENTURY Semi automatic die cutting machine works well because the boxes now stay rigid and secure; an essential feature with packaging up items for storage or posting.

A great thing about carton box cutting machines is that they make lots of boxes quickly. Due to their versatile nature, high-speed cardboard cutters can make quick and precise cuts through any type of box. That is why they can produce so many boxes in very short period. This is especially useful for companies who are required to have a high number of boxes at any given time, and could help them address customer demands more promptly.

Last but not least the carton box cutting technology has revolutionized the packaging industry, in this post we shall discuss how. Having the ability to create boxes in custom shapes and sizes allow businesses pack their items better put more comfortably. The CENTURY Second hand die cutting machine also can make boxes using sizes that fill the product entirely and not having to depend on predefined shapes.

The company is committed to Carton box die cutting machine outstanding after-sales service. It has a comprehensive system that can provide professional technical assistance, maintenance and customer service and resolve any issues. The company is the only "Flatbed Die-cutting Machine RD Centre" in China recognized by the China Packaging Federation and the "Shandong Flatbed Technology RD Center" awarded by the Shandong Packaging and Printing Association, and has robust RD capabilities. We can offer our clients advanced products and solutions through continuous investment in RD as well as conducting technological innovation and improving the quality of our products.

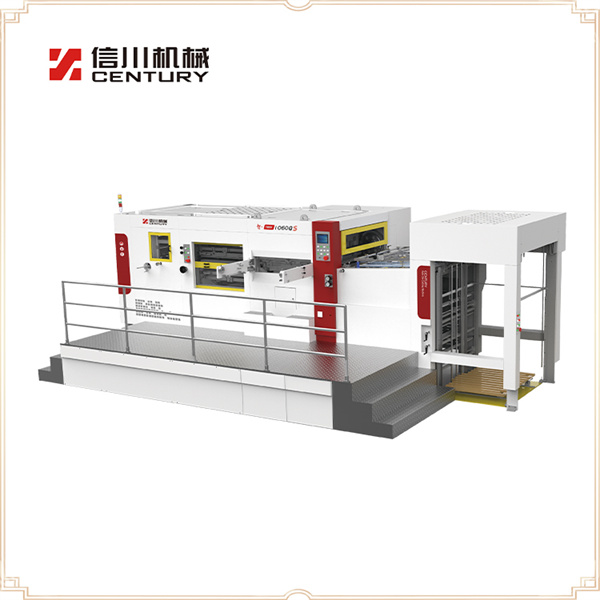

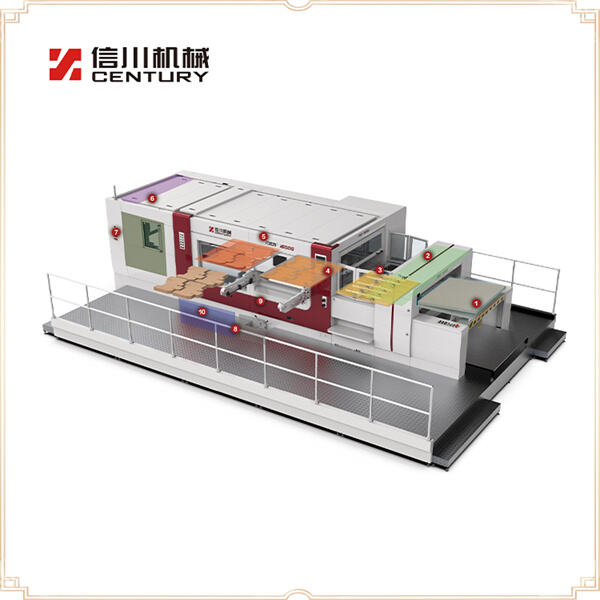

CENTURY's flatbed die-cutting machine can die-cut not only corrugated paper however, it can also cut cardboard and other materials. It offers a broad range of applications that can meet the requirements of different clients. The equipment uses advanced technology and high-quality components including high-strength tooth and precise mechanisms for gripping paper to ensure the accuracy of cutting paper. Die-cutting pressures are accurate and uniform and less need to reprint plates. Certain models are capable of reaching an maximum speed of 7,500 sheets per hour. It has an efficient working rate, and can be matched by pre-press equipment for improved the overall efficiency of production. The new front-edge paper feeding fully automated intelligent die-cutting machine has achieved intelligent and automated technological advancements regarding production efficiency, quality of cardboard quality and safety assurance which significantly improve the production efficiency of order Carton box die cutting machine.

Shandong Century Machinery Co., Ltd. was founded in Carton box die cutting machine. It's a ISO9001 quality management system that has been certified as well as a CE certified business. It is a high-tech regional enterprise and a national "little giant" business. It is a company with a lot of acclaim and respect in the field. The company currently has more than 50 expert scientists and a seasoned technical RD and production team to ensure the high-quality and performance of its products. The products offered by the company are extensively sold across 29 provinces, cities and autonomous regions of China and exported to more than 60 countries, including the United Kingdom. It has a wide customer base as well as a market, and its products have been acknowledged by both foreign and domestic customers.

Our products have experienced Carton box die cutting machine innovation and improvement. We also have launched a variety of distinctive products. For example, the cassette paper feeding machine makes use of vector "zero" point motion to feed paper, which has zero friction and zero displacement, which fundamentally solves scratch marks on the surface of printing; the left and right push gauge system of the bridge piece fulfills the requirements of various printing registrations, and assures precise placement of the paper. There are a range of products models, such as 930 10, 1050, 1600, 1300 1450, 1620 etc. for semi-automatic products, and 1050, 1080 1450, 1650 etc. Fully automatic products can be customized to meet the needs of the customers. CENTURY Machinery flatbed die-cutting machines are cheaper than imported products. In addition its quality and performance is able to meet the demands of customers by offering a superior cost performance.