An automatic platen die cutting machine is another category of a machine which is utilized to cut different materials into distinct shapes and dimensions. This is an amazing machine because it can cut materials such as paper, cardboard or even fabric. These CENTURY materials are frequently used to create things like clothes, packages as well as playthings. Because of the high precision, it can cut shapes being as accurate with the auto platen machine. That is significant because when individuals are doing work, the aim to having factors operate flawlessly with each other. This Die Cutting Machine machine is so fast in cutting materials which can perform the work of any other machines, and this also saves a lot of time nowadays for the workers.

Cutting materials used to be a manual process and for the higher quality work scissors would do so. It was a very long process, sometimes leading to workers feeling fatigued and jaded. Then the Second hand die cutting machine auto platen machines cam and revolutionized it all. The CENTURY cutting materials, these marvellous machines worked faster and gave quicker results than had been before. They were also able to get very clean precise cuts; which was important since they cut pieces for clothes, toys or packaging. However, this new technology had the effect of making die cutting operations “easier” as the machines took over more and harder work freeing workers up to undertake other important task sigs.

In the auto platen machine, there is a special part that works as support and holds onto the material when it cut. This Semi automatic die cutting machine is great because it holds everything firm as well, so you have cleaner lines. The CENTURY machine starts cutting material when the workers press a button. It is a fast and efficient tool, which indicates that it does not consume longs hours to complete the process. It means informed workers will be able to produce a huge number of pieces in relatively short order, an asset at some companies where speed counts for everything.

Anytime you are creating something like clothes, packages or toys…the end user expects everything to look good. They want every last bit, and they all need to line up perfectly with the rest of them. The auto platen machine does this by very accurately cutting materials. This Automatic die cutting machine way, each piece will be roughly the same size and shape giving you a uniform final product. Once the materials are cut, workers can put a whole lot together to create gorgeous end products that consumers will be thrilled with.

The auto platen machine can do this much faster than a person. This New Material means a worker can make more pieces in less time. As they can produce more items in a short duration, businesses have the potential to sell greater quantities of products. This is extremely vital for companies that are aspiring to become great. The auto platen machine also saves the money because it does not require more manpower to perform cutting tasks. That savings in labour costs can instead be allocated to other key business divisions, improving your competitiveness.

The Auto platen die cutting machine is dedicated to providing top after-sales support. It offers a complete system that can provide professional technical support, maintenance and customer care, as well as solve any issues. The company boasts an impressive RD capability and is the only Chinese "Flatbed Technology RD Centre" that has been recognized by the Shandong Packaging and Printing Association. Continuously investing in RD funds, as well as executing technological innovation and product updates We can supply customers with advanced technological solutions and products.

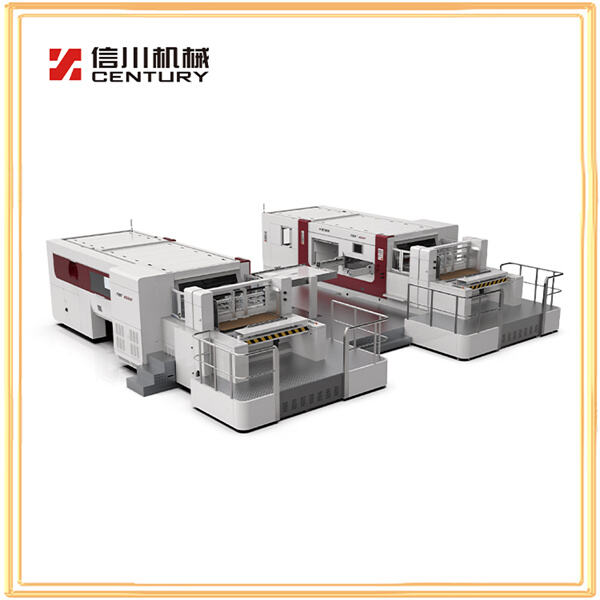

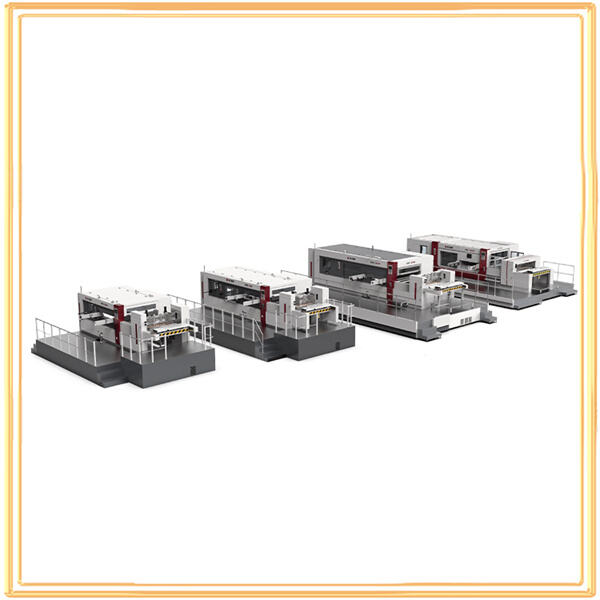

The flatbed die cutting machine from CENTURY is able to cut corrugated papers, but other materials. It can be utilized for a range of purposes and meet the needs of many clients. To ensure precision in die cutting this equipment is constructed with high-quality materials and modern technology, including high-strength tooth and a precise mechanism for gripping paper. The pressure used to cut paper is uniform which means that there is less Auto platen die cutting machine of plates and is also precise and long-lasting. Certain models can achieve an maximum speed of 7,500 sheets per hour, with high efficiency of operation, and can be paired with pre-press equipment to enhance the overall efficiency of production. The latest front-edge paper-feeding completely automated intelligent cutting die is a breakthrough technological advancement that has been fully designed to be automated and has improved production efficiency as well as the quality of cardboard used and security.

Auto platen die cutting machine was founded in 2008. It is a ISO9001 quality management system that is certified and CE certified business. It is a high-tech regional enterprise and an expert nationwide "little giant" company. It has a high degree of recognition and reputation in the business. It has more than fifty professionals in the field and an impressive RD team and production team. This assures high-quality and efficiency. The company's products are sold efficiently in 29 provinces and cities and autonomous regions across China, and exported to more than 60 countries including the United Kingdom, Turkey, Japan, etc. It has a wide customer base as well as market share, and its products have been accepted by both domestic and international customers.

Our Auto platen die cutting machine have undergone continuous innovation and improvement. We also launched several innovative products. The cassette-type paper feed machine includes, for instance, a vector "zero point" motion to feed the paper with zero friction and with no displacement. This eliminates the scratching problem on the surface of the print. There is a wide range of product models available, such as 930, 1050, 1160, 1300 1450, 1620 etc. to semi-automatic equipment, and 1050, 1080, 1450, 1650, etc. Fully automatic machines can be tailored to meet the demands of customers. CENTURY Machinery flatbed die-cutting machines are more affordable than imported ones. The performance and quality of the product can satisfy the requirements of customers while also being cost-effective.