Maszyny do wykrawania są prawdopodobnie najlepszymi wynalazkami, aby uzyskać fajne kształty i wzory! Na podstawowym poziomie są specjalistycznymi narzędziami dla osób i firm, które muszą wykonać dziesiątki lub tysiące identycznych cięć. Ważne jest to CENTURY Die cięcia oszczędzają nasz czas, a także pomagają nam w bezbolesnej pracy, dzięki czemu możemy łatwo wykonać zadanie. Dlatego w większości przypadków używa się automatycznych maszyn do wykrawania; dzięki czemu możesz robić rzeczy szybciej i z mniejszą liczbą pracowników. Pomoże Ci to zrobić więcej za mniej, co ostatecznie pozwoli zaoszczędzić pieniądze. Najlepszą częścią tych maszyn jest to, że nie musisz mieć kreatywnej kości w swoim ciele ani martwić się, że cokolwiek wymyślisz, będzie wyglądać inaczej niż dopracowane i profesjonalnie.

Produktywność jest ważna dla wszystkich firm, a jeśli Twoja firma zajmuje się rękodziełem, te automatyczne wykrawarki pozwolą Ci stworzyć więcej produktów. Te maszyny są specjalnie zaprojektowane, aby zmniejszyć doskonałą ofertę produktów w znacznie krótszym czasie. CENTURY Używana maszyna do sztancowania dużo łatwiej, gdy próbujesz szybko produkować duże partie produktów. Wydawanie cennej energii na budowanie pojedynczych maszyn i części, zamiast pracowników, byłoby stratą czasu, ale możesz zaoszczędzić tę cenną pracę na wytwarzanie części za pomocą automatycznej wykrawarki. Więc Twoja firma ostatecznie dostarcza więcej towarów do sprzedawcy detalicznego w krótszym czasie, co skutkuje efektywnie produktywnym i zadowolonym klientem.

To jest niezbędna praca do wykonania w celu rozwiązania trudnych problemów dla tych, którzy chcą wprowadzać innowacje w sposobie tworzenia w miejscu pracy i w firmie. Zamiast ręcznie wycinać swoje przedmioty, automatyczna maszyna do wykrawania wykona pracę za Ciebie w mgnieniu oka. Od początku do końca maszyny te działają jak krajalnica, krojąc żywność. Możesz załadować materiał, przetworzyć CENTURY Półautomatyczna maszyna do sztancowania i nawet same tną na wymiar! To wygodne pole, które odznaczasz i przechodzisz do ważniejszych rzeczy, które napędzają Twój biznes.

Firmy, które korzystają z automatycznego wykrawania, czerpią z niego korzyści na wiele sposobów. Po pierwsze, zobaczysz, że są naprawdę proste w obsłudze. Nawet nowicjusz może się ich nauczyć, są bardzo łatwe w obsłudze. Te funkcje mogą zapewnić nawet sztywne cięcie dla maszyn o regulowanej prędkości i wysokiej precyzji. Są to bestie zaprojektowane do produkcji wielkoseryjnej (mniej pracy). Ponadto umożliwiają szybszą produkcję, zapewniając jednocześnie mniejszą liczbę błędów.

To naprawdę może zrewolucjonizować sposób, w jaki TWORZYSZ na swojej maszynie do wykrawania. To pozwoli im skrócić czas przetwarzania, który zajmują, tak aby pobierać prawidłowe informacje. To również sprawia, że cały bałagan, cięcie materiałów jest łatwiejsze i mogę pozwolić na większą dokładność i spójne wyniki. Są również inteligentne, ponieważ mogą formować się do określonych materiałów bez konieczności całkowitej zmiany. W ten sposób możesz uniknąć długich przerw i nie uszkodzić bieżącego stanu operacji. A wykorzystanie automatyzacji wykrawania zapewnia również minimalizację błędów i wad, co z kolei oznacza, że Twoje produkty są lepsze.

Firma produkująca automatyczne maszyny do wykrawania jest oddana zapewnianiu doskonałych usług posprzedażowych. Posiada kompleksowy system zapewniający fachową pomoc techniczną, konserwację i obsługę klienta, a także rozwiązuje wszystkie problemy. Firma jest liderem w zakresie zdolności RD i jest jedynym w Chinach „Centrum RD technologii płaskich”, które zostało uznane przez Shandong Packaging and Printing Association. Ciągłe inwestowanie w fundusze RD, wprowadzanie innowacji technologicznych oraz udoskonaleń i aktualizacji produktów pozwala nam dostarczać klientom najwyższej klasy rozwiązania technologiczne i produkty.

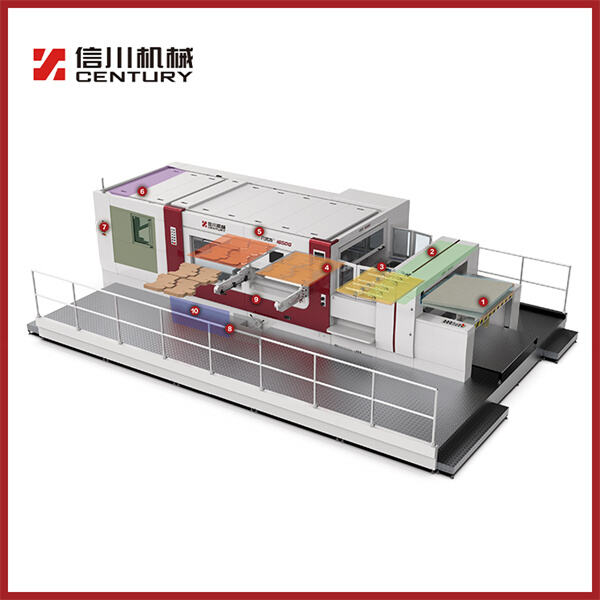

Maszyna do wykrawania płaskiego CENTURY jest w stanie ciąć papier falisty, ale także inne materiały. Ma szeroki zakres zastosowań, które mogą spełnić wymagania różnych klientów. Aby zapewnić precyzję wykrawania, sprzęt wykorzystuje wysokiej jakości materiały i najnowszą technologię, która obejmuje zęby o wysokiej wytrzymałości i precyzyjny mechanizm chwytania papieru. Naciski wykrawania są stałe i precyzyjne, a także występuje mniej przedruków płyt. Niektóre modele są w stanie osiągnąć maksymalną prędkość 7,500 arkuszy na godzinę. Ma wysoką wydajność działania i może być łączona z urządzeniami do przygotowania do druku w celu poprawy ogólnej wydajności produkcji. Automatyczna maszyna do wykrawania z przednim podawaniem papieru w pełni zautomatyzowana, inteligentna maszyna do wykrawania osiągnęła inteligentne i zautomatyzowane przełomy technologiczne w procesie produkcyjnym, a także zapewnienie jakości i bezpieczeństwa tektury, co znacznie poprawia wydajność zmiany zamówień.

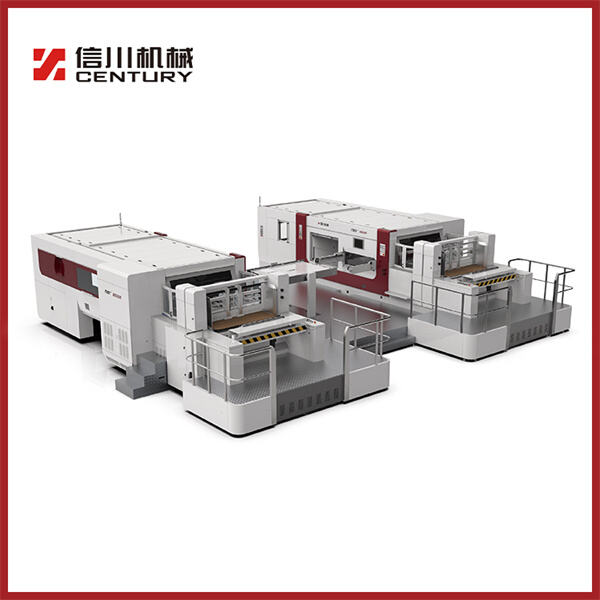

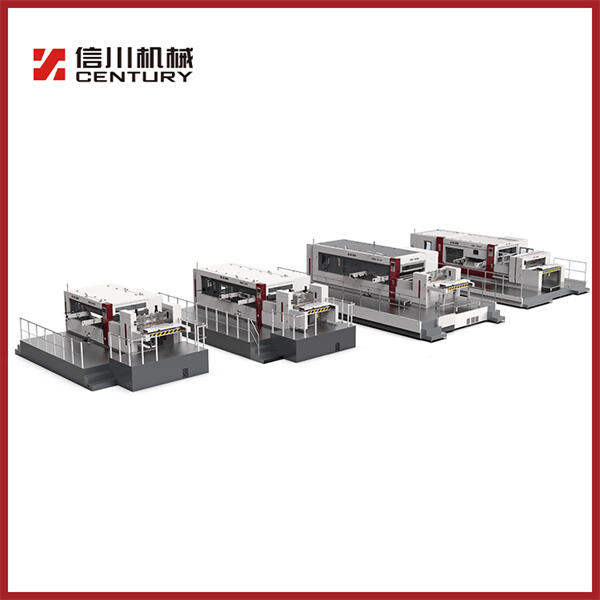

Ciągle ulepszamy i wprowadzamy innowacje w naszych produktach, a także wypuściliśmy automatyczną maszynę do wykrawania wyróżniających się produktów. Na przykład, maszyna do podawania papieru z kasetą wykorzystuje wektorowy ruch punktu „zerowego”, aby podawać papier bez tarcia i przemieszczenia, co zasadniczo rozwiązuje problem zarysowań na zadrukowanej powierzchni. Lewy i prawy wskaźnik nacisku elementu mostkowego jest w stanie sprostać potrzebom różnych rejestracji druku i zapewnia precyzyjne pozycjonowanie tektury. Istnieje szeroki zakres opcji modeli, w tym 930 1050, 1160 1300 1450, 1620 itd. dla produktów półautomatycznych i 1050,1080, 1450 1650, XNUMX itd. W pełni automatyczne maszyny mogą być modyfikowane, aby spełnić wymagania klientów. Maszyny do wykrawania płaskiego CENTURY Machinery są tańsze niż produkty importowane. Jakość i wydajność produktu są w stanie sprostać wymaganiom klienta, oprócz tego, że są opłacalne.

Shandong Century Machinery Co., Ltd. została założona w Automatyczna maszyna do wykrawania. Jest to system zarządzania jakością ISO9001, który został certyfikowany, a także firma posiadająca certyfikat CE. Jest to regionalne przedsiębiorstwo high-tech i krajowy „mały gigant”. Jest to firma ciesząca się dużym uznaniem i szacunkiem w tej dziedzinie. Firma obecnie zatrudnia ponad 50 ekspertów naukowych i doświadczony zespół techniczny RD i produkcyjny, aby zapewnić wysoką jakość i wydajność swoich produktów. Produkty oferowane przez firmę są szeroko sprzedawane w 29 prowincjach, miastach i regionach autonomicznych Chin i eksportowane do ponad 60 krajów, w tym Wielkiej Brytanii. Ma szeroką bazę klientów, a także rynek, a jej produkty zostały uznane zarówno przez klientów zagranicznych, jak i krajowych.